Accurately Predicting Vibration Behavior

Florian Hollaus

27.05.2025

Precise Predictions for Dynamic Structures Using the Example of a Mower

If components in a dynamic machine structure are not firmly connected to each other, a variety of vibration phenomena can occur, and simulations and measurements can show significant differences. Dr. Franz-Josef Falkner from the Management Center Innsbruck University of Applied Sciences is researching how dynamics can be better represented in the simulation and how results can be predicted more accurately. We spoke to him about this at the CADFEM Conference in Salzburg.

Franz, you gave a presentation titled “Is it Correct? Matching Simulation and Experiment in Structural Dynamics.” For those who couldn’t attend, could you briefly summarize the key points?

Gladly. In my presentation, I talked about how we can use measurement data to validate structural dynamic simulation models. Often, simulation results do not match reality. To improve prediction quality, the model needs to be adjusted. There are some excellent methods for doing this.

As an example, you used a mower from the agricultural machinery manufacturer Pöttinger. How was the matching process carried out, and what challenges did you face?

The Pöttinger mower is a prime example of a dynamically stressed structure with complex vibration phenomena. We wanted to predict these with our simulation models. The structure is complex and contains, among other things, several components that are not firmly connected. Simulation and measurement often differed, especially regarding the eigenfrequencies. We had to find methods to bring the two worlds – testing and simulation – together and improve the prediction accuracy. Since the research was part of a project, we had a bit more freedom to develop new ideas.

Success means the simulation is constantly improving as we can better represent dynamics. Our goal is to identify things in the simulation that we haven’t seen before.

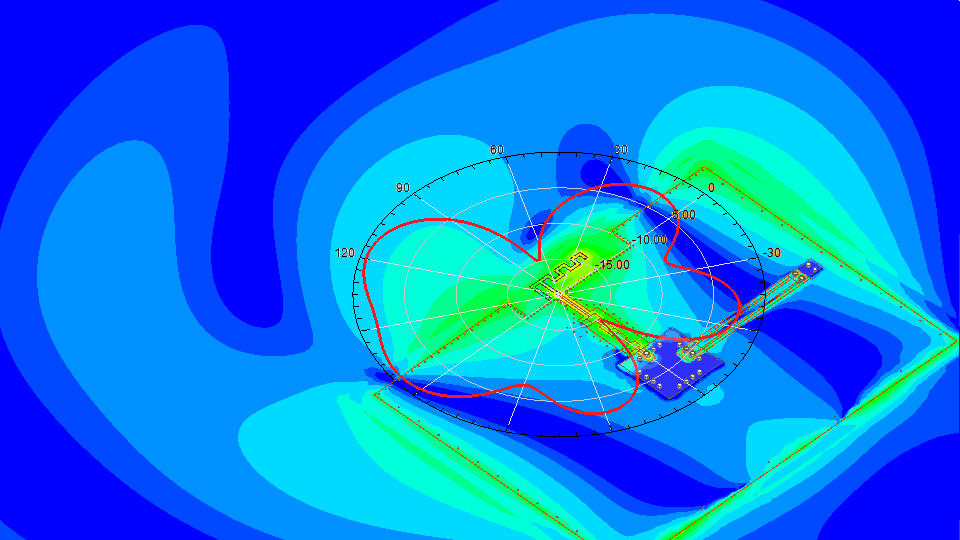

Matching Measurement and Simulation | © Dr. Franz-Josef Falkner, MCI | Die Unternehmerische Hochschule®

What technical tools and methods did you use for this matching process?

At first glance, the matching process seems relatively simple. First, we use the NVH tool in Ansys, which allows us to import measurement data in UNV format and compare it directly with the simulated eigenmodes. We can then quantitatively assess how well or poorly the measured and calculated values align using the MAC matrix. Another important tool is Ansys optiSLang, which we use for sensitivity analysis and optimization. We also program our own objective functions to adjust specific parameters, which gives us flexibility. This helps us develop methods that can benefit industry partners.

How long does such a matching process take?

It largely depends on the complexity of the structure. For simple components, it’s relatively fast. However, for large assemblies with many parts, it’s more time-consuming. A key factor is the contacts, which behave very differently in dynamics compared to statics. So, it's difficult to say exactly how long the matching process will take. Our goal is to provide the calculation engineer with the right tools so they can reach the solution as quickly as possible.

Details, Tips and Tricks

Learn more about the topic “Is it Correct? Matching Simulation and Experiment in Structural Dynamics” and download Franz-Josef Falkner’s presentation (in German).

Download Now!

What were the key takeaways from this project?

At first glance, they are fairly simple things: Proper documentation of the experiment is crucial, as different departments are often involved, and the test engineer sees things differently from the simulation engineer. Additionally, a sound knowledge of structural dynamics is required to be able to correctly interpret results and make targeted adjustments. Another key takeaway is that dynamics is not static. Therefore, simulation models in structural dynamics should always be validated.

What does success mean to you in a simulation project?

Success means the simulation is constantly improving as we can better represent dynamics. Our goal is to identify things in the simulation that we haven’t seen before. This brings us closer to our goal of bridging the worlds of measurement and simulation.

Franz, thank you for the conversation.

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.

You can watch the full conversation with Dr. Franz-Josef Falkner here: