Minimize the vibration potential of noise sources with simulation

Gerhard Friederici

17.06.2025

Brake by Wire? Yes, but without any unwanted noise generation!

Alongside reliability, noise is an important aspect that must be considered during product development. Simulations help us to better understand and optimize noise behavior. This is explained in more detail here using an example from the development of brake systems (brake-by-wire).

Schalter sind standardisierte Serienprodukte. Das beschriebene Projekt wurde am Schaltwerk des Modells 506U durchgeführt | © JUNG

Braking systems and their further development are an important part of the product range in the automotive industry. Safety, efficiency and comfort are the focus of development. New brake systems based on the brake-by-wire principle transmit the driver's braking intention purely electrically via sensors on the brake pedal to the corresponding modules for generating brake pressure.

Short braking distances and low maintenance costs

Brake-by-wire in conjunction with electric drives not only ensures short braking distances and low maintenance costs, but also better recovery of braking energy. Here, electricity is generated by recuperation in deceleration situations, whereby a seamless transition from regenerative braking (recuperation) to the actual wheel brake must occur. Although there is no longer a hydraulic connection between the brake pedal and the brake actuators, the braking feel should be the same as when using hydraulic brakes.

Simulation is an integral part of the development process for brake manufacturers as well. In most cases, the challenges faced by development engineers can be quickly and effectively overcome with the help of simulation, especially when an undesirable behavior occurs whose cause is not immediately apparent. This makes it possible, for example, to ensure that the feel of the brake pedal is always the same for the driver, even during recuperation.

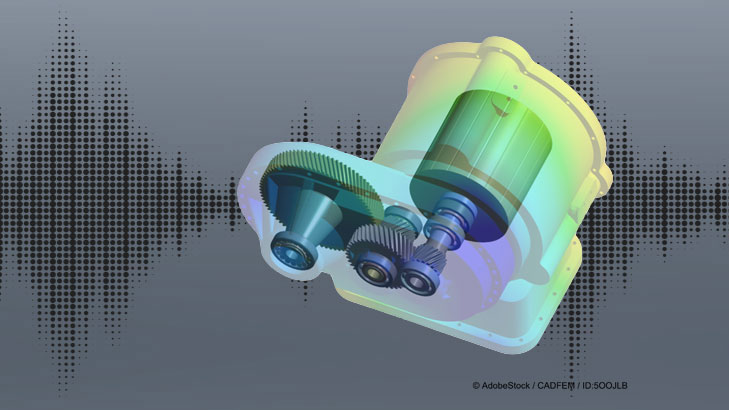

Using simulations to better understand noise behavior

Since comfort – preferably no unwanted noise – is an important aspect in the design of a braking system, in addition to reliability, simulation is also used to better understand noise behavior. However, acoustic simulations are somewhat uncharted territory for many of the customer’s development engineers. CADFEM offers training to introduce them to the topic. After analyzing the respective task, CADFEM recommends a customized training program for the relevant engineers. The subsequent support of the customer in acoustic analyses by experienced consulting colleagues from CADFEM leads to fast and reliable results.

The squealing of brakes can be analyzed in detail and significantly reduced using simulations | © CADFEM Germany GmbH

An example of unwanted noise behavior that is not immediately apparent would be a “ping” noise that may occasionally occur when braking. This could be perceived by the occupants as a warning sound from the vehicle system – similar to the fasten seat belt, close doors or fuel reserve sounds – and cause them concern. In such cases, simulation can be used to localize the cause of the noise and then take measures to prevent such noises from occurring.

Understanding and Simulating Technical Friction Effects

In this training you will deal with the mechanism behind the most important friction-related phenomena. You will learn to anticipate issues caused by friction in advance or find a comprehensive and sound solution to any problem arising from the operation of your products.

Changing the natural frequency of the spiral spring or housing

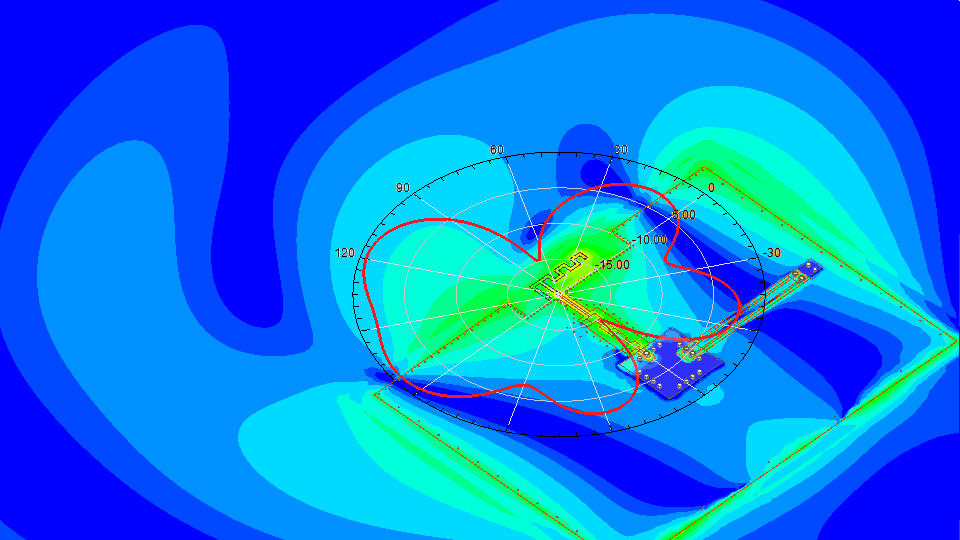

In this example, analyses of the rubber stamp, including the spring, the spring housing and the support, showed that unwanted vibrations can occur in certain situations. The reasons for noise generation in the corresponding components was suspected to be due to the low damping coefficient of steel. A closer look at the natural frequencies of the springs and their housings, along with a harmonic acoustic analysis, determined the noise level as a function of frequency. ANSYS simulations of the dynamic behavior of the complete spring system showed a correlation between the natural frequencies of the spiral spring used and its housing.

This makes it possible to localize unwanted noises, such as the “ping” sound, at an early stage, before real prototypes are built. By simply varying the spring, the natural frequencies of the spiral spring and housing could be decoupled, thus eliminating the “ping” noises.

In-depth understanding of the acoustic behavior of braking systems

Based on a special training program and in-depth workshops with CADFEM specialists, the customer's calculation engineers have expanded their simulations to include acoustics and were able to localize the sources of noise, which could then be minimized. All in all, this has given the engineers a deeper understanding of the dynamics and acoustic behavior of braking systems. By conducting virtual tests, the company was able to achieve significant savings in both time and materials before a real prototype was produced.

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.