Automating Transformer Design with PyAEDT: Hitachi Energy Insights

Klaus Kuboth

11.09.2025

Streamlining transformer development with automation and multiphysics simulation

Irene Woyna from Hitachi Energy shares how her team uses PyAEDT to automate multiphysics workflows in transformer development. PyAEDT is a Python client library that interacts directly with the Ansys Electronics Desktop (AEDT) API. By integrating electromagnetic, thermal, and structural simulations, they reduce variability and improve efficiency.

Irene, you are speaking at the CADFEM conference about exporting transformer losses distribution using PyAEDT. Could you give us a quick overview of the content of your presentation?

I’ll explain how we streamline our product development using PyAEDT to automate multiphysics workflows. The main goal in our transformer product development is to streamline the entire process. We want to meet customer requirements at the lowest possible cost and within a reasonable timeframe. One of the key aspects is thermal management of transformers. For every transformer we design, thermal management is one of the key points. And that’s what I’ll focus on in my talk.

What are the core simulation steps involved in such a multiphysics analysis?

I’m an electrical engineer, so I naturally focus on electromagnetics. We start with electromagnetic simulations to calculate loss distribution—sometimes in 2D, sometimes in 3D—considering effects like skin effect, proximity effect, different geometries, materials, and load conditions. For thermal simulations, we use in-house analytical tools, often implemented in MATLAB, and sometimes 2D CFD. We also look at structural integrity by calculating electromagnetic forces and using them in structural simulations.

What is PyAEDT?

PyAEDT is an open-source Python library for automating Ansys Electronics Desktop (AEDT).

Strategic Benefits of Workflow Automation with PyAEDT

- Full workflow automation

- API-driven flexibility

- Integration with external tools (e.g., MATLAB, Excel)

- Reusable extensions & toolkits

- Open-source & GitHub-based

If I think of a multiphysics workflow, I think of Ansys Workbench and connecting the different parts. Which role plays the PyAEDT or in general the Python access?

We want full control over the entire workflow—not just simulations, but also analytical blocks and test data. We don’t want Ansys Workbench or any other tool to control the process. Python enables us to integrate all components into one script-driven workflow.

Do engineers need to be expert programmers to use PyAEDT?

I’m an electrical engineer. In university, I had to learn the basics of programming, but that's it. So I'm not a professional programmer, and I think this applies to almost every attendee of this conference. And this is exactly the strength of PyAEDT—you don't have to be a super Python expert to use PyAEDT and to automate your workflows. Yes, you need to learn a couple of things, but a professional programmer—that is not needed.

Methodology & Workflow

Toolchain: Ansys Maxwell + PyAEDT for automating loss calculation and exporting to generic formats (.csv) for CFD tools.

Use Cases: Dry-Type Transformers and Hotspot Detection

- 10 kVA Dry-Type Transformer

- Objective: Assess the impact of low-voltage lead-outs on temperature distribution.

- Approach: 3D Maxwell model including lead-outs → Export losses via PyAEDT → 2D CFD model in MATLAB.

- Result: Local loss peaks on the lead-out side are accurately captured and thermally evaluated. - Network Model for Hotspot Identification

- Objective: Efficiently model 3D temperature distribution in windings.

- Approach: Discretization into a thermal network → Consideration of conductor length, convection, and conduction.

- Result: Hotspots are reliably identified, even in complex winding structures.

When we talk about automation, it takes a lot of effort to first make it run. What are the advantages once it's running?

This is a good point. If you give the same transformer design to five engineers today and repeat the task in two years, you’ll get ten different results. Human variation is inevitable. So what we can do—we can take all these five engineers, discuss, combine the best practices, and plug all these five best practices into one automated workflow.

So that means if I have the automated workflow, it's following always the same steps, the same rules. Everyone—or the program—uses the same rules all the time. Do you think there are other applications in your company or in general where this multiphysics workflow including PyAEDT is important?

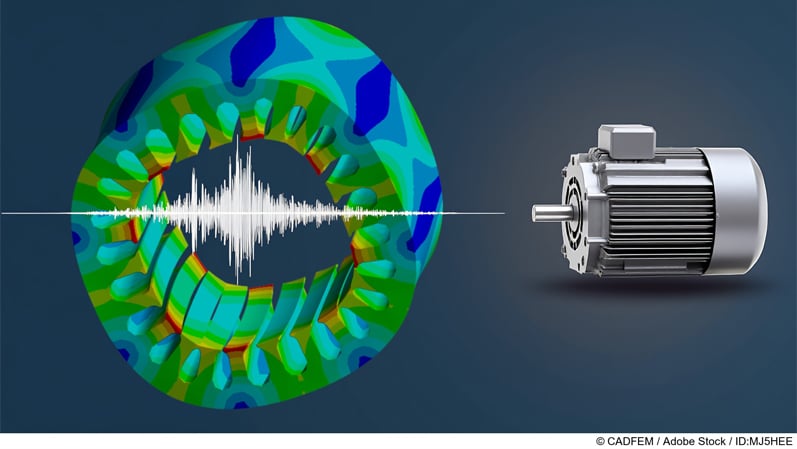

Oh yes. Our top priority is the electrothermal workflow, but structural integrity of the transformers is very important as well. In this case, we do electromagnetic simulation with Ansys Maxwell and couple it with structural simulation to see if the transformer, for example, withstands short-circuit forces. Another area is NVH—noise, vibration, and harshness—which is important for distribution transformers near residential areas. We also look into system-level simulations, like calculating RLC parameters for circuit models. Additionally, system or circuit simulation would be another case. We calculate the RLC parameters of transformers, for example, capacitances between the winding turns, and then we use those parameters in a circuit simulation.

Details, Tips and Tricks: Reduce manual efforts with PyAEDT

PyAEDT enables seamless integration of electromagnetic simulation and thermal evaluation. The workflow is transferable to other transformer types and thermal methods. Strategic benefits: Faster design cycles, higher model fidelity, better decision-making – with reduced manual effort. For more information on the workflow and PyAEDT download the presentation.

Download the presentation

If you make such a workflow, there must be some value behind it. What's the big advantage of this one?

Transformers are a 150-year-old technology and most people know how they work. One could ask: “Why all this? Why do we have dozens of R&D engineers thinking about this?” When we approach 99 % of all the design work, it gets harder and harder. So we are maybe at this last 1 % to try to optimize the performance of our transformers. And we need to turn every stone and look everywhere—how can we streamline and how can we optimize everything? Even small improvements in efficiency or weight can have a big impact. Multiphysics, optimization, automation play an important role.

As we get closer to the limit—the physical limit—we need to examine things in more detail. That’s the challenging part, and it also brings value to the company. So whether it’s 99.6% or 99.7% efficiency—that difference really matters. So, what will be your next steps?

My presentation is about electrothermal simulation focussing on the winding losses, which are the dominant loss component in transformers. But we also may need to look into other loss components—for example, core losses or losses in some structural parts. That would be the immediate next step. But then, looking a bit further, we are really interested in automating electromagnetic-structural workflows.

But what we try to do in the future is to containerize these workflows so that a user only has an interface to this workflow and doesn't have to care where the simulation runs—if it is cloud resource, virtual machines, whatever.

So we might see you at the next CADFEM Conference with an update?

I hope so! I’m looking forward to that.Irene, thank you for this interview.

Watch the full interview with Irene Woyna:

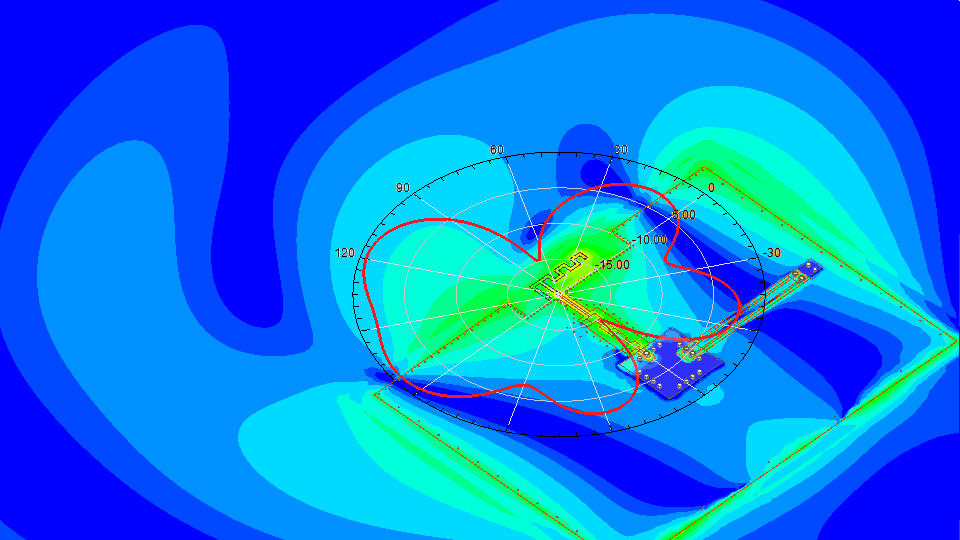

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.

Seminar Tips

-

Using Python to Automate Tasks within Ansys Maxwell

In this training, you will learn to use the IronPython interface as well as PyAEDT libraries and API to automate workflows in Ansys Maxwell. This training is offered as a 2-day course.

-

Python Primer for Ansys

In this training, you will learn the basics of Python programming for using PyAnsys and automating your Ansys simulations. This training is offered as a self-paced eLearning course.