Comment Dieffenbacher automatise les tâches courantes de simulation

Alexander Kunz

19.02.2025

Conversation with Marco Trusheim, computational engineer at Dieffenbacher

Pour les entreprises d'aujourd'hui, être innovant est plus important que jamais. Cette innovation peut aussi venir de la simplification des étapes du workflow, comme le montre l'exemple du fabricant de machines et d'équipements Dieffenbacher.

© Dieffenbacher

Chez Dieffenbacher, une toolbox complète a été développée pour la solution de simulation Ansys Mechanical, qui automatise de nombreuses étapes de calcul récurrentes. Marco Trusheim, ingénieur en calcul chez Dieffenbacher, décrit dans cette interview la genèse du projet, les avantages de la toolbox et l'importance de l'ancrer dans Ansys Minerva pour centraliser la gestion des processus et des données de simulation (SPDM).

Marc Vidal: M. Trusheim, vous utilisez Ansys Mechanical pour les simulations structurelles et mécaniques chez Dieffenbacher. En plus, il existe une toolbox que vous avez développée en interne. Pouvez-vous nous expliquer brièvement de quoi il s'agit ?

Marco Trusheim: Nous effectuons de nombreuses simulations dans le cadre de notre travail de développement, en particulier pour les analyses structurelles et mécaniques. Compte tenu du nombre considérable de tâches récurrentes, il était évident que nous devions utiliser l'automatisation pour simplifier les workflows en les standardisant, réduire les d'erreurs potentielles et assurer la traçabilité et la transparence des processus. C'est ce que nous avons fait : les paramètres et les conditions limites qui ne changent pratiquement pas, mais qui doivent être pris en compte à chaque fois sont stockés dans la toolbox. Il s'agit notamment de la température, de la pression, du matériau et de la corrosion. Nos ingénieurs gagnent ainsi énormément de temps, ce qui leur permet de pleinement se concentrer sur les aspects les plus complexes du calcul et de la conception. La gestion des données est aussi plus aisée et plus cohérente.

At a glance: The Dieffenbacher Toolbox for structural mechanics calculations with Ansys Mechanical | © Dieffenbacher

Marc Vidal : Qu'est-ce qui a poussé à la mise en œuvre d’une telle automatisation avec la création de la toolbox ?

Marco Trusheim : L'inspiration nous est venue d'un ancien collègue qui a toujours eu un intérêt pour la programmation et son potentiel de simplification des processus. Il possédait également une grande expertise d'Ansys. C'est lors d'une formation CADFEM que l'impulsion décisive pour le projet lui a été donnée. Un exemple d'un autre client CADFEM, Krones, a été présenté et c'est à ce moment qu'il s'est vraiment rendu compte de l'étendue des possibilités de personnalisation d'Ansys et de leur énorme potentiel. Il s’est très vite lancé sur ce projet et c’est ainsi que notre toolbox a pris forme. CADFEM nous a aidés à relever le défis en répondant à nos questions, avec un transfert de connaissances conséquent vers Dieffenbacher. Finalement, mon collègue a réussi à mettre sur pied notre propre solution, créant une toolbox parfaitement adaptée à nos besoins.

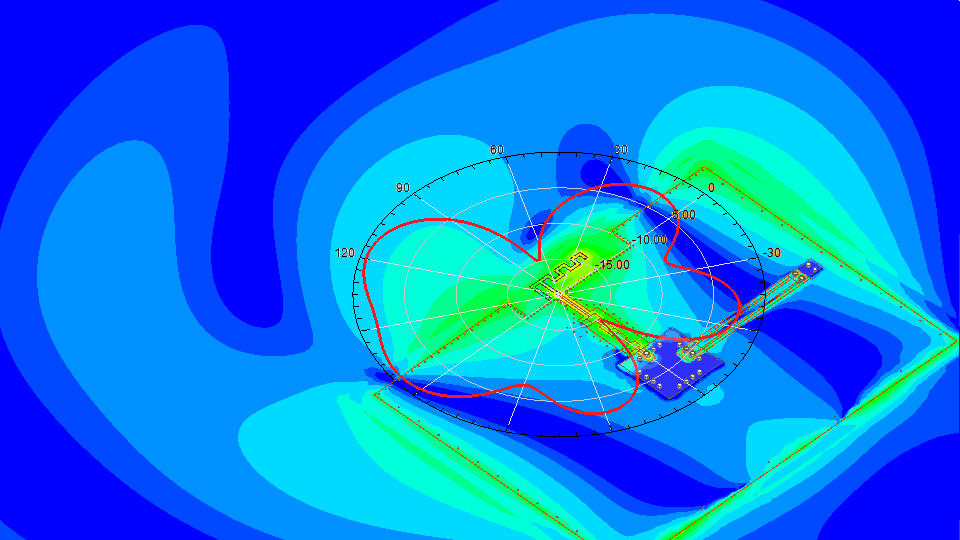

La toolbox permet d'automatiser les étapes de travail en vert sur l’illustration, pour la plupart chronophages et récurrentes. L'image est un extrait de la présentation (en allemand) « ACT-Toolbar zur Automatisierung von Druckstoßfestigkeits-Berechnungen » tenue par Marco Trusheim lors de la conférence CADFEM 2024. Les personnes intéressées peuvent le demander ci-dessous.| © Dieffenbacher

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

Présentation “ACT-Toolbar for the automation of pressure shock resistance calculations”

Marco Trusheim, Dieffenbacher, présenté à la CADFEM Conference 2024 à Darmstadt (Note: les slides sont en allemand)

Download here for free

Marc Vidal : En résumé, quels sont les avantages de la toolbox pour votre entreprise ?

Marco Trusheim : La toolbox offre de nombreux avantages. Avant tout, elle amène des gains de temps considérables. Les tâches de routine qui étaient effectuées manuellement, telles que l'affectation de matériaux à certains composants et la définition de conditions limites standard sur de nombreuses surfaces, sont maintenant automatisées et réalisées beaucoup plus rapidement. La toolbox augmente également la fiabilité des résultats, car elle réduit la probabilité d'erreurs humaines, avec moins d'entrées manuelles nécessaires. L'intégration de modules de texte standard et de résultats de calcul améliore également la cohérence de nos rapports techniques, ce qui accroît la qualité de notre gestion de projet. Il est également important que ce soit intuitif et facile à utiliser.

Marc Vidal : Comment la toolbox est-elle intégrée aux processus de développement et de simulation chez Dieffenbacher ?

Marco Trusheim : Chez Dieffenbacher, nous avons introduit Ansys Minerva qui gère de manière centralisée tous nos processus et nos données de simulation. Nous profitons énormément de la transparence, de la rapidité et de la clarté qui en découlent. Dès le départ, nous avions envisagé d'intégrer la toolbox. Cette intégration permet de transférer toutes les conditions requises essentielles au projet, directement de la commande à la toolbox et donc au modèle de calcul, ce qui automatise fortement le processus de saisie des données et réduit les sources d'erreur.

Des processus plus efficaces et plus de transparence : gestion centralisée des données grâce à Ansys Minerva

Implémentation réussie et utilisation du produit Ansys Minerva chez DIEFFENBACHER

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.