Magnetic properties of ferrite cores: Using simulation for material analysis

Gerhard Friederici

15.07.2025

Herbert Hackl: “For us, measurement and simulation always go hand in hand”

Determine magnetic properties, master electromagnetic compatibility, automate repetitive processes: We spoke with DI Dr. Herbert Hackl, Senior Scientist at Silicon Austria Labs research center, about how he and his team in Graz analyze the magnetic properties of ferrite cores to enable simulations with realistic models.

Herbert, your topic at the CADFEM Conference Salzburg is the use of pyAEDT and HFSS to determine the permeability of ferrite cores for the design of EMC filters. What is your presentation about?

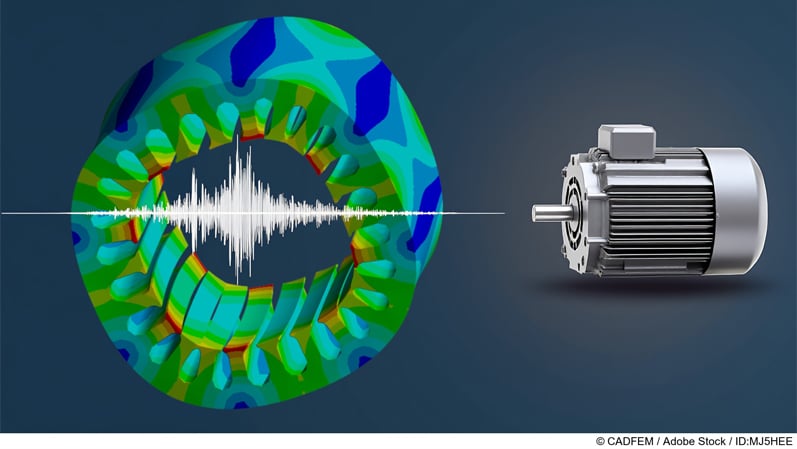

Ferrites are important components in electrical engineering that guide magnetic fields and give them direction. They are used to build inductors, which in turn are used to build filters. Ferrite cores are found almost everywhere—for example, in the transformers of chargers. If simulations are to be carried out and realistic models created, the exact properties of the ferromagnetic material must be known. My presentation is about how we determine these properties.

For which specific case did you develop this approach?

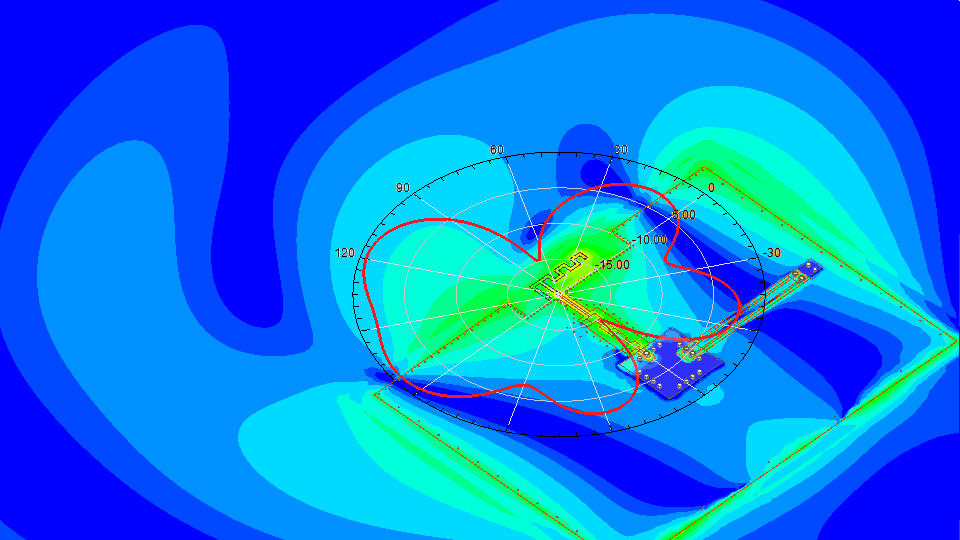

The method was developed by our cooperation partner BMW Steyr and was first presented by Dr. Martin Heinisch at the EMC Symposium 2023 in Seibersdorf. It focused on the simulation-based prediction of the damping properties of magnetic cores in traction inverters, i.e., in the drivetrain of modern electric vehicles. There is an inverter that drives the motor and at the same time generates unwanted electrical interference. These disturbances are minimized with filters. A simulation can clarify where exactly these filters should ideally be inserted and which material and size are optimal. But the method is not only useful in the automotive sector—it is generally applicable wherever such filters are used. In the Power Electronics department at Silicon Austria Labs, determining the material properties of magnetic components is a standard task.

Do ferrite cores also play a role in renewable energy and energy storage?

Absolutely—for example, in power conversion from AC to DC. Our power grids operate with alternating current, while batteries use direct current. For the conversion, we need transformers that work with ferrite cores.

Automation plays a major role for us. In the lab, we use Python to automate measurements that are repeated daily. For simulation, we write a small code and only need to click once to run the script.

How can you determine the exact material properties of the ferrite cores?

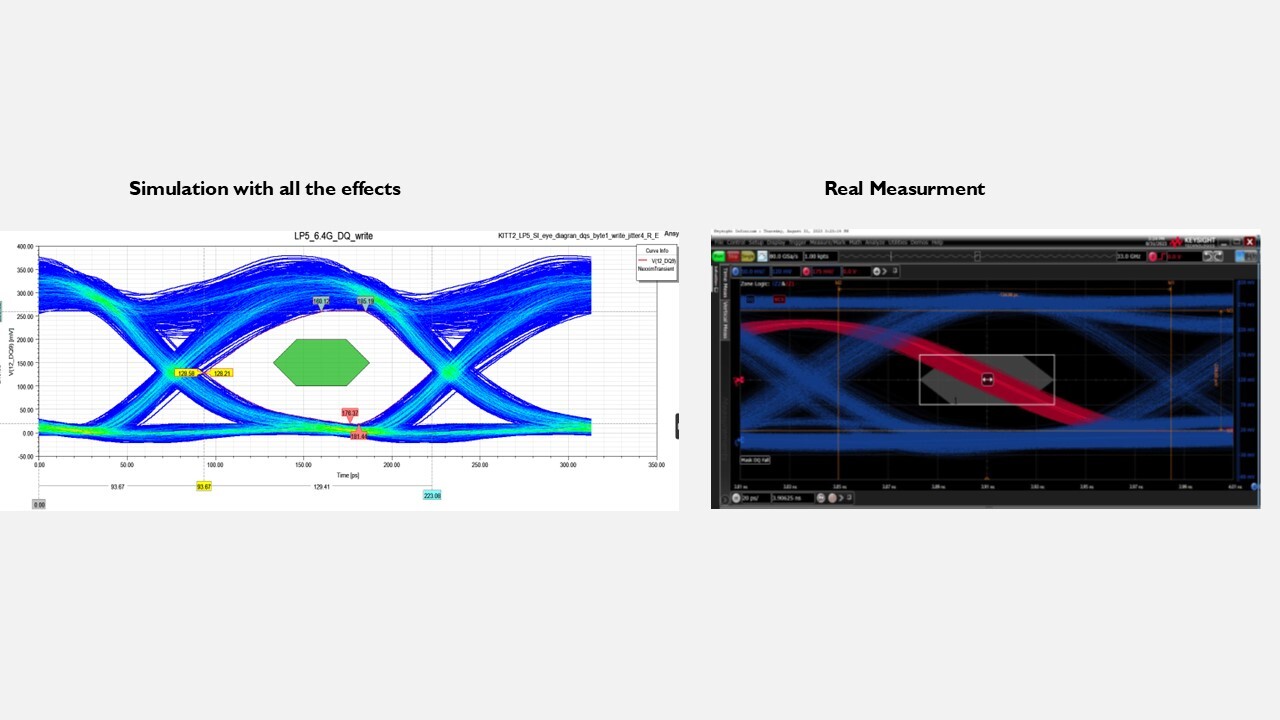

That’s actually not trivial. Ideally, you measure these properties directly on a sample. If I can physically touch the ferrite, it works well. But that’s not always the case. Often, it’s sealed, painted, or embedded in epoxy resin. Then we combine measurements with simulations. In the simulation model, we represent the material as realistically as possible, including plastic housing and adhesive. The results are then compared with indirect measurements. This way, we can determine the magnetic properties of the ferrite core.

How large is your team and what is your role?

Our power electronics team at Silicon Austria Labs includes more than 60 people, about ten of whom work in the field of EMC—electromagnetic compatibility. My main task is simulation using commercial tools like Ansys, but also measurement technology in the lab. For us, measurement and simulation always go hand in hand.

You’re working on a project in cooperation with BMW. What is it about?

It’s about prototypes of components that BMW has manufactured by suppliers. Before they are ordered in large quantities, it must be ensured that they deliver the desired performance in the car. Simulations help verify whether the component works optimally or if something still needs to be changed. We work very closely with the EMC team at BMW Steyr.

Our Tip: Seminar “Analyzing and Improving EMC with Simulation & Measurement”

Facing an EMC test? Learn how to quickly identify and effectively resolve EMC-critical areas in your electronic device using measurement and simulation methods.

What challenges must be overcome in the simulation of electromagnetic compatibility?

One of the biggest challenges is that the real system is often not precisely known. The art is to still incorporate all the real properties into the simulation model that are necessary—not too many and not too few. If the model is too complex, the calculation takes forever. If it’s too simple, the result is inaccurate.

To what extent have you automated processes?

Automation plays a major role for us, both in the lab and in simulation. In the lab, we use Python to automate measurements that are repeated daily. My presentation also covers how the material extraction workflow can be supported with a Python script. In simulation, sometimes you have to click 20 times to get a result—or we write a small code and only need to click once to run the script.

Thank you for the interview, Herbert.

Watch the full conversation with Dr. Herbert Hackl here:

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.