Simulation-based product configuration: How WAGO is transforming its e-shop

Alexander Kunz

07.10.2025

Digital customer service with small simulation models

Simulations are more than just a tool for development engineers. WAGO, a specialist in electrical connection technology, uses simulations at other points in the product lifecycle as well. In the e-shop they help customers select the right connectors and terminals. Using simplified simulation models, customers can independently check the suitability of the connectors and terminals for the thermal and dynamic electrical loads to which they will be exposed.

© WAGO

Connect, measure, control, and mesh – WAGO’s more than 25,000 catalog products ensure reliable and intelligent power and data flow worldwide across a wide range of applications and industries.

They are developed using simulation-based Ansys software. WAGO computational engineers use precise product models – including pluggable connectors, terminals and control systems – to develop, analyze and optimize their properties and operating principles and ensure their reliability.

What are the advantages of virtual prototypes in product development?

They are literally “digital twins” of real products – with additional advantages: They are able to illustrate the smallest details and hidden interactions, enable rapid variant studies and “what-if” scenarios. This provides a deeper understanding of the behavior of components and systems. Unlike physical prototypes, these virtual prototypes are also location-independent and can be flexibly transferred.

This is an important digitalization component that also benefits other areas of the company, including product management, service, and technical sales. Simulation models supplement customer communication with details that go far beyond the content of data sheets.

The challenge: These models are enormous; preparing them individually for customer projects takes time. This is often lacking at WAGO, because development work takes priority over internal “simulation-as-a-service”, which is increasingly in demand.

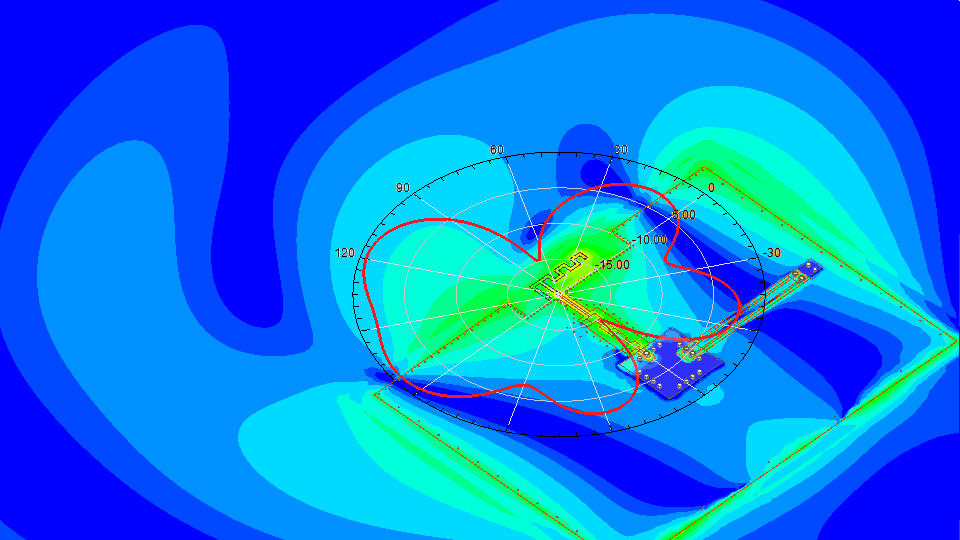

3D FEM model of a connector in WAGO: Detailed, but large and computationally intensive. | © WAGO

Reduced Order Models for Thermoelectric Simulation

This article is based on the presentation “Reduced Order Models for Thermoelectric Simulation – On-Demand Simulation in Customer Service” given by Dr. Wilhelm Rust from WAGO (in German language) at the CADFEM Conference 2025 in Hanover.

Request the presentation (German)

Efficient simulation: Focus on the essentials with reduced order models and Ansys TwinBuilder

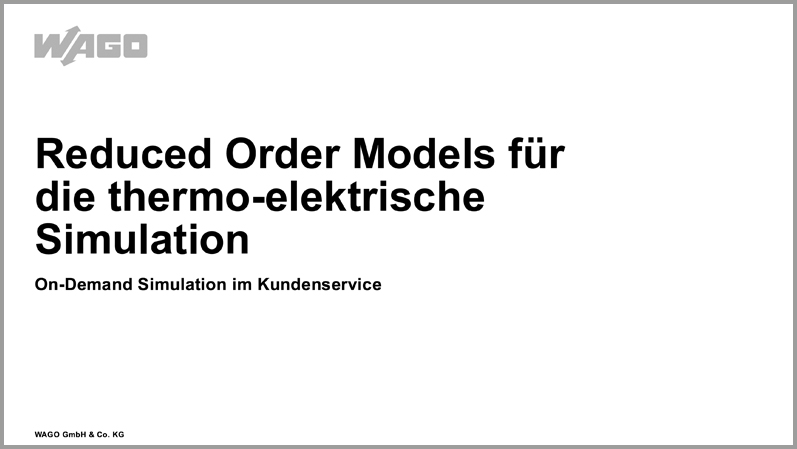

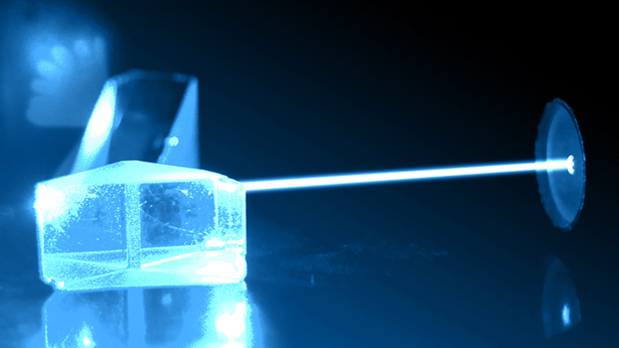

This constellation gave rise to a new idea. The starting point is the large digital models that the calculation team at WAGO creates for all products in Ansys Mechanical. They contain all details, even those that are of secondary importance to customers. In fact, for connectors and PCB terminals, only a few electrical and thermal properties are important for the decisive customer criterion, namely electrical load capacity during subsequent use. Only these are exported to a reduced 1D model with a fraction of the previous size, which can be transferred to databases, linked to other functions, embedded in systems, and subjected to various current load profiles.

Reduced order model of the electrical and thermal properties decisive for connectivity. | © WAGO

The software tool for generating reduced order models (ROMs) is called „Model Order Reduction inside Ansys“ and was developed by Ansys specialist CADFEM in cooperation with the Steinbeis Transfer Center in Lower Saxony.

Based on the reduced data, a large number of dynamic customer-specific load profiles are then simulated using the Ansys TwinBuilder software. With minimal effort, individual results are generated and made available to customers or interested parties as part of support or sales processes.

Machine learning in the WAGO E-Shop: Intelligent product selection based on thermal criteria

WAGO has gone one step further: A machine learning model has been developed, trained, and validated using countless load cases for each product. In collaboration with other company divisions – Sales, Service, IT, Marketing – the simulation option is now part of the web shop. WAGO customers can check the basic suitability of electrical connectors and PCB terminals according to electrical and thermal criteria and taking into account their individual boundary conditions 24/7, independently and in compliance with data protection regulations. In view of ever-smaller design spaces, this allows the smallest possible component to be determined that meets the thermal specifications under the given current and ambient temperature.

Simulations based on reduced order models of products in the WAGO e-shop make configuration and selection easier for customers. | © WAGO

This does not eliminate the need for personal consultation and customer support. However, you start with the simulation models already customized at a point in time when many fundamental questions have already been clarified, which significantly speeds up the overall process for everyone involved.

More customer service, less routine work: Scalable digitalization at WAGO

The first products are already available in various versions, with more to follow quickly. With this simulation-based configurator, WAGO has gained a unique selling point in its markets. Like all digital solutions, this new option gives WAGO customers much more flexibility and autonomy in the procurement of standard components. At the same time, it relieves WAGO employees in development, service, and sales of time-consuming and repetitive tasks and efficiently scales existing knowledge within the company.

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.