CETIM determines whether pressure equipment is suitable for transporting hydrogen

Elise Deville

17.06.2025

Is your pressure equipment suitable for transporting hydrogen?

Pressurized equipment is a closed vessel containing a certain volume of liquid or gaseous fluid at a certain temperature and pressure. This combination represents a quantity of energy, which, in the case of hypothetical failure, would have disastrous consequences. Accidents throughout history have shown that pressure risk management is essential and must be taken into account right from the design stage.

© Adobe Stock / CETIM / CADFEM

Compliance with safety standards for pressure equipment

Pressure equipment safety is based on compliance with regulatory texts and technical documents. These standards define sizing and monitoring criteria to prevent failures. CETIM plays a central role in this field, thanks to its historical involvement and its contributions to the development groups for national, European and international codes and standards. This expertise ensures that pressure equipment remains in service safely.

Energy transition and challenges for hydrogen-powered equipment

Faced with the energy transition and the boom in hydrogen applications, new players are seeking to penetrate this fast-growing market. At the same time, other manufacturers want to adapt their practices to integrate this new use. CETIM is supporting these developments by offering services to assess the harmfulness of defects, such as cracks, to check their compatibility with hydrogen. This makes it possible to estimate the residual life cycle of equipment.

Assessing the suitability for use of pressure equipment

CETIM is asked to carry out calculations to assess the suitability for use of pressure equipment with defects. This approach goes beyond conventional inspections to optimize maintenance operations. The aim is to extend the life cycle of equipment despite defects, while guaranteeing safe operation. In this way, operators can avoid costly repairs or premature equipment replacement.

Visualization of the stress field on a section of pipe under thickness | © CETIM

FFS (Fitness For Service) methodology

FFS studies are carried out in three key stages:

- Assessment of the harmfulness of defects according to a technical reference system for in-service monitoring of pressure equipment.

- Fault propagation under load cycles until the next inspection or until a critical threshold is reached.

- Assessment of the harmfulness of future defects to estimate the residual life of equipment.

This approach ensures safety while optimizing maintenance costs

CETIM solution: a two-phase approach

CETIM uses API code 579-1/ASME FFS-1 for in-service monitoring of pressure equipment. The solution is divided into two phases:

- Phase 1: Characterization of damage using non-destructive testing (NDT) methods to identify defects.

- Phase 2: Determination of stresses in component thickness using analytical calculations (DBF) or finite element analysis (DBA) with Ansys tools for optimum accuracy.

This methodology makes it possible to accurately model the state of equipment in real time.

TSE : The agrivoltaic canopy

TSE is one of France's leading solar energy producers. In concrete terms, they are accelerating the energy transition, as well as protecting agriculture from climatic hazards. They have developed a sustainable energy production solution: the agricultural shading system. Ansys enabled them to simulate strong fluid/structure interactions using a digital wind tunnel under Ansys Fluent.

.png)

Numerical Simulation and Modeling with Ansys

For an accurate assessment, CETIM uses Ansys SpaceClaim to model the geometry of equipment, taking into account the evolution of the structure. Material properties are integrated into Ansys Workbench with a linear elastic behavior law. Loads and boundary conditions are applied in Ansys Mechanical. The extracted stresses are used to assess the harmfulness of defects in accordance with the rules of the technical reference framework.

FAD analysis: Determining the harmfulness of defects

The harmfulness of defects is determined by placing a characteristic point on the FAD diagram, which depends on defect geometry, material and loading. Two quantities are analyzed:

- L_r^p (Load Ratio): Indicator of failure due to excessive deformation.

- K_r (Toughness Ratio): Indicates sudden failure.

If the point is below the threshold curve, the defect is stable and acceptable. Otherwise, the fault is unstable and requires immediate action.

Residual life and fault propagation studies

If a fault is stable, a residual life study is carried out to estimate the equipment's remaining operating time. Crack propagation is assessed using the Paris law, taking into account load fluctuations. Loading cycles are analyzed to update defect dimensions, enabling us to determine the number of cycles permissible before failure.

The importance of regulations for the safety of pressure equipment

The safety of pressure equipment is crucial because of the potential danger in the event of failure. Regulations impose strict safety requirements, complemented by normative documents to ensure compliance. The current industrial context is driving operators to adapt their installations for new applications, such as hydrogen, thus increasing the risks associated with pressure.

Why choose CETIM for ESP evaluation?

CETIM combines NDT and calculation skills, using a mixed approach between analytical and numerical calculation. Ansys tools (SpaceClaim and Mechanical) are essential to model structures and exploit results accurately. The reliability of this method means that informed decisions can be taken to keep equipment in service, while optimizing maintenance costs.

Reactivity and efficiency: CETIM's key assets

The responsiveness of CETIM, together with its mastery of current regulations and the codes/standards to be applied, are essential to providing operators with fast, accurate results, thus facilitating decision-making. The mixed approach favored by CETIM saves time compared with full numerical analyses. This guarantees a reliable and rapid assessment of the fitness for use of pressure equipment, contributing to safe and optimized operation.

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

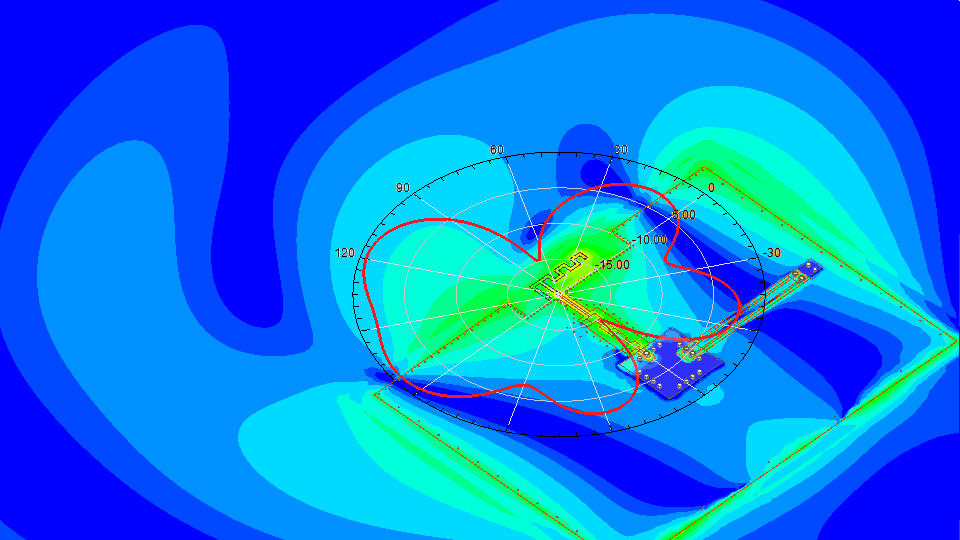

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.