More than just Cable Cars – How Model Based Systems Engineering Found Its Way into Inauen-Schätti

Christophe Ozier-Lafontaine

05.02.2026

An interview about personal turning points, systems engineering and the future of functional safety.

Model-Based Systems Engineering (MBSE) is changing the way complex systems are developed. Dr. Daniel Henseler from Swiss company Inauen-Schätti AG demonstrates how this methodology not only shortens development times but also raises quality and safety to a whole new level. We spoke with him about how MBSE is transforming product development.

© Inauen-Schätti AG

Summary

- Quality and safety as the foundation: Inauen-Schätti relies on model-based approaches and tools such as Ansys medini Analyze to identify risks early and systematically integrate functional safety.

- A personal path to MBSE: Daniel Henseler brings experience from the startup world and establishes MBSE as a strategic tool for efficient and transparent development processes.

- Partnerships as the key: With support from CADFEM, the implementation of new methods succeeds. Through training, consulting, and technical enablement, MBSE becomes a driver of efficiency for the future.

How Does Inauen-Schätti Achieve Quality, Safety and Reliability?

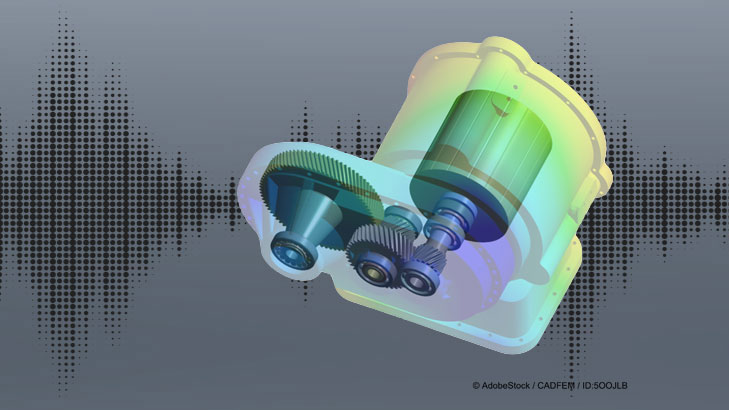

The development of the KSB 2.0 compact cable car and the inclined lift systems presented a fundamental engineering challenge: Both are complex systems that require a precise understanding of interfaces and interactions.

To efficiently manage such complexity, there are model-based systems engineering approaches that use block and interface diagrams to derive analyses for functional safety (e.g. FMEA). Without such a direct methodology, development teams have to go through numerous iteration loops – with considerable time and cost implications.

The biggest challenge here is not the product itself, but rather the systematic application and internalization of such a model-based approach.

The solution lies in a robust model structure that enables systematic analysis of complex interactions and can be supplemented by subsequent structural mechanical calculations.

Implementation and Key Role of CADFEM

CADFEM played a decisive role in the successful implementation of the pilot project – with technical expertise and commercial consulting. Its in-depth knowledge of model-based approaches such as FMEApex was essential for the project implementation in 2023.

The implementation was carried out internally, with targeted training sessions led by Dr Daniel Henseler, who independently supervised the pilot project. Over a period of six months, this pilot study validated the advantages of the model-based strategy and established it as a practical framework for future projects.

In addition, CADFEM provided strategic advice on software use and in-depth training so that Inauen-Schätti's engineers could confidently apply the new methodology. Support from CADFEM remained consistent and reliable throughout the entire process.

Strategic Benefits: MBSE as an Efficiency Driver

For companies, introducing MBSE is more than just a technical upgrade. It is a strategic step towards shortening development cycles, improving quality and reducing costs in the long term.

- Pilot projects are already showing clear advantages:

- Time savings of up to 50–70% through early error detection

- Improved communication through visual model structures

- Higher product quality through clear system representations

- Greater safety through traceable risk analyses

CADFEM played a central role as a partner – with training, technical consulting and strategic support. The combination of tool expertise and methodological support – enablement – paves the way.

More information on Reliable Model-Based Safe SystemsWhen Expertise Meets Corporate Culture

In a world of functional safety and systems engineering, it's not just methods and tools that drive innovation—it's people with vision. One of them is Daniel Henseler. As a project engineer and deputy technical manager at Inauen-Schätti, he not only brings technical expertise to the table, but also a story that shows how personal experience and strategic thinking can work together. We spoke with him about his journey from start-up to cable car technology, the role of Ansys medini Analyze and CADFEM, and how model-based systems engineering (MBSE) is changing product development.

Mr. Henseler, you have worked extensively with model-based systems engineering. How did that come about?

It started in 2023 when I was working for a start-up called Compliag AG. We were a small team specializing in regulated industries such as medical technology and life sciences. Our strength lay in our agility – we were able to test and implement new methods quickly. MBSE was key for us in efficiently managing complex regulatory requirements.

What was special about your work there?

I combined the FMEA 7-step methodology according to AIAG/VDA with model-based approaches and developed my own concept from this. The block diagrams I created for this were developed in a separate tool, where I was able to model the system structure, functions and interfaces in detail.

And how did Ansys medini Analyze come into play?

That was a very decisive step. I was able to import the block diagrams I had prepared directly into the software and perform the complete FMEA analysis there. Medini enabled me to assess risks, assign measures and even link the argumentation to simulation results. The working method was extremely efficient. Everything was traceable, visually clear and methodically clean. I was really impressed by how quickly and structured I was able to work. Medini greatly strengthened my argumentation strategy towards customers and colleagues – because everything was transparent and reproducible.

I was really impressed by CADFEM Support and the medini Analyze tool. The transparency, efficiency and clarity of the working method helped me to implement my ideas quickly and convincingly.

You then moved to Inauen-Schätti – a completely different environment. How was that transition?

The difference is enormous. Compliag was an agile consulting and development start-up with 3–4 permanent employees and a network of experts. Inauen-Schätti is a medium-sized mechanical engineering company with around 70 employees that implements complex infrastructure projects – cable cars, inclined lifts, special-purpose machines. The requirements are more technical and the structures more established.

What does that mean for your work?

At Compliag, it was often about regulatory consulting and rapid implementation. At Inauen-Schätti, it's about long-term product development, high safety requirements and complex technical systems. But this is exactly where I can contribute my knowledge – for example, through block diagrams, structured risk analyses and the introduction of MBSE into the development processes.

What is the environment like at Inauen-Schätti for implementation?

Very open. The company has a strong culture of innovation and is willing to test new methods. We have already held initial workshops on functional safety, and MBSE is increasingly being recognized as a strategic tool – especially in view of upcoming regulatory requirements.

This combination of technical support, training and individual guidance shows that CADFEM is not just a software provider, but a trusted engineering partner.

Mr. Henseler, we have talked a lot about functional safety. But regarding the new Machinery Regulation and the Cyber Resilience Act – what else is in store for companies like Inauen-Schätti?

Functional safety is currently the central issue for us. We are working on systematically integrating it into our development processes – with MBSE as the methodological basis. The new Machinery Directive will reinforce this, as it requires a structured approach to safety-related functions. We have already held initial internal workshops on this topic.

And cyber resilience?

That is an additional, new field – it is only just beginning. In future, the Machinery Directive will also address digital risks – for example, through requirements for secure control systems, interfaces or software updates. I see MBSE as the key here again: only if we model our systems completely – including digital components – can we identify and mitigate risks at an early stage.

Innovation Needs Enthusiastic People Like Daniel Henseler

Regulatory requirements are changing – and with them the expectations placed on engineering teams. The new Machinery Directive focuses on functional safety, while the Cyber Resilience Act extends this framework to include digital resilience. For companies, this means that product development must not only be safe, but also resilient and traceable.

But methods alone are not enough. It takes people who drive these issues forward – with experience, enthusiasm and strategic vision. Daniel Henseler is exactly that person at Inauen-Schätti: a driver of innovation, a champion of functional safety and a bridge builder between classic mechanical engineering and the digital future. His experience in the start-up sector, his enthusiasm for tools such as Ansys medini Analyze and his systemic thinking make him a key figure in digital transformation.

Editorial

Christophe Ozier-Lafontaine

CADFEM (Suisse) AG

+41 21 614 80 48

christophe.ozier-lafontaine@cadfem.ch