Designing Smarter Liquid Crystal Optics with Simulation

Gerhard Friederici

22.12.2025

Liquid Crystal Optics Reimagined: Interview with Daniel Jimmerskog

In the race to deliver immersive AR/VR experiences, optical precision is key. Daniel Jimmerskog explains how ultra-thin, tunable liquid crystal lenses — optimized through advanced simulation tools like Ansys Zemax and Ansys Lumerical — are redefining the boundaries of smart optics. From design to validation, simulation accelerates innovation and improves performance across applications.

Summary

- Innovative AR/VR Optics: FlexEnable develops ultra-thin, flexible liquid crystal lenses optimized for immersive AR/VR experiences using advanced simulation tools.

- Simulation as a Key Technology: Tools like Ansys Zemax and Lumerical enable precise design optimization, improved image quality, and reduced development time.

- Future Outlook: API-driven interoperability allows for custom solutions and automated simulations – a strategic advantage for FlexEnable.

What is FlexEnable primarily working on in product development?

FlexEnable Technology is a spin-off from the Cavendish Lab at Cambridge University and focuses mainly on technologies in the field of organic thin-film transistors. Key components are optical liquid crystal elements, especially used in augmented reality applications. With these ultra-thin, flexible liquid crystal optics, we can steer, modulate, and focus light.

This groundbreaking optical technology can be biaxially shaped around existing components – a dream for any industrial designer. Since the optical elements can be directly adapted to designed surfaces, products can be made even more compact. At the same time, optical performance is improved compared to planar glass components. Lightweight optics and high user comfort are crucial for VR/AR devices. Reducing device weight and easing image focusing enhance immersion and help prevent dizziness for users.

What are the biggest challenges in developing AR optics?

In developing and optimizing optical lenses and complementary dimming technology, we at FlexEnable rely on tunable liquid crystal lenses, or LC lenses. We’ve been able to develop new LC lenses, based on a special type of plastic called TAC, made from triacetate cellulose. It’s a material with extremely low birefringence, high transmission, and low haze.

This allows us to actively adjust focus so that perceived and actual image depth can be consistently aligned, balancing focus differences between virtual and real image elements in the field of view. Thanks to Ansys simulation software and support from CADFEM, we’ve significantly improved comfort and image contrast in VR/AR devices.

With a thickness of less than 100 micrometers – thinner than a human hair – and a weight of a fraction of a gram, LC lenses can also be stacked to increase focal length. By combining them with other flexible LC cells, additional functions – such as dimming for virtual objects in all environments – can be integrated.

Our tip: Discover the future of AR optics

Download the full presentation by Daniel Jimmerskog from the CADFEM Conference and explore how FlexEnable is revolutionizing AR with tunable liquid crystal lenses and advanced simulation techniques.

Download the presentation

Can you describe the use of simulation more concretely?

For example, we performed efficient optimization of multilayer elements using the Ansys Lumerical Stack tool. It implements the transfer matrix method – an analytical solution to Maxwell’s equations for thin-film scenarios. Since optimizing transmission and transmission range is crucial for us, the numerical stacks were very useful. They allowed us to eliminate surface reflections by carefully selecting the right thicknesses of the involved layers.

We produce lenses that perform very well on-axis, but performance drops off-axis. That’s why we constantly work with simulation support to improve performance there too.

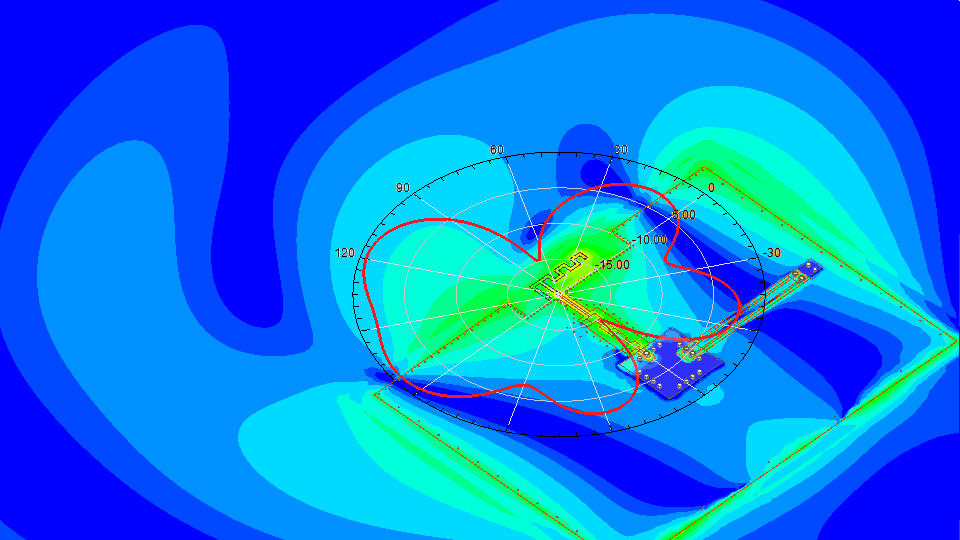

Two-component optical model for angled propagation through a LC cell. | © Flexenable Technology Ltd.

What does this optimization look like in practice?

Our goal was to create single-layer LC lenses with high off-axis performance and excellent image quality. To do this, we had to design the electrode layout so that we achieved point-by-point optimization of molecular orientation through angle-dependent optical response.

We work with an optical model that allows us to generate a symmetrical optical lens profile with an oval voltage profile. This oval voltage profile is influenced by the LC material and the properties of near-eye applications.

This approach can be extended to other optical systems, such as wide-angle imaging or endoscopic devices. Refractive corrections are also possible, for example to adjust the eye’s refractive power in cases of visual impairment.

Why is such effort necessary for liquid crystal lenses?

Since liquid crystals generally consist of elongated molecules, they are naturally asymmetric. To create a liquid crystal lens with a radially symmetric profile, multiple cells can be stacked. Essentially, a symmetrical system is created by balancing the different layers.

However, we found that the same type of characteristics can be generated in a single layer if the molecular orientations in different areas of the lens are optimized accordingly. Simulation with Ansys Zemax was very helpful in this.

Was the effort worth it?

Absolutely – it was more than worth it! As with many technical and physical tasks, it’s also about limiting complexity. That’s why we wanted to reduce the number of layers, partly for cost reasons and also to minimize haze and blur effects.

So we built a design optimization pipeline that allows us to simulate optical performance from various viewing angles. This enabled us to optimize the electrode structure so that we essentially obtained a symmetrical optical lens profile from this anisotropic liquid crystal environment.

Simulation is truly the key optimization tool. It allows us to identify the most important levers of optimization before we even go into the lab and conduct experiments. This significantly shortens development times.

Can you give more examples of the potential benefits of using simulation tools?

Ansys Zemax is definitely our most important foundation for simulations and my first point of contact for any kind of optical evaluation. I recently used it to design the imaging part of an interferometer. This is now an important device for us to evaluate the optical performance of lenses and similar components. We use it for imaging optics and also for illumination optics. This allows us to iterate quickly to optimize designs for both our products and technologies in our lab.

Another application example is the Physical Optical Propagation Toolbox, which is very useful in liquid crystal optics for Fresnel resets of the light phase. The lens catalogue also helps us set up tabletop experiments faster when standard components from suppliers can be used in the design.

Additionally, Zemax software has the capability to calculate the propagation of a complex electric field, enabling precise analysis of other effects such as diffraction in a system.

What future prospects do you see for using Ansys software at FlexEnable?

I already see the breadth of interoperability between the platforms that Ansys offers. The integration of optical applications is also progressing. When considering the combined use of different products, one of the most important criteria is the existence of APIs.

For example, the Python API for Zemax, which handles most of the connections between different software systems, enables comprehensive system coupling. With the simulation tools provided by Ansys, custom solutions can be realized relatively easily. We’re excited to explore this. It also enables application-specific simulation automation, allowing us to tackle upcoming challenges more efficiently, quickly, and safely. This strengthens and expands our market position and enables us to present better and more powerful AR/VR solutions to our customers.

Watch now the interview with Daniel Jimmerskog (Senior Optical Design Engineer, FlexEnable):

Request trial version

Would you like to know how simulation can accelerate your product development? Talk to us and discover how you can achieve real competitive advantages with simulation. Register now to try out our free trial version for 30 days: Request trial version

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.