Smart Optics through Simulation: How AR Innovations Lead to Market Advantage

Gerhard Friederici

22.10.2025

FlexEnable Accelerates AR Breakthroughs

Augmented reality and virtual reality are transforming industries from automotive to healthcare. But immersive experiences require more than just powerful processors: they require intelligent, lightweight optics. FlexEnable demonstrates how simulation-based development of ultra-thin liquid crystal lenses can dramatically shorten innovation cycles and provide a decisive market advantage.

AR and VR applications are already transforming industries and opening new dimensions of human-machine interaction. Whether in medical technology, industrial applications and remote maintenance of industrial systems, in vehicle cockpits or entertainment – immersive technologies create efficiency, safety, and new business models. However, the technical challenges are significant.

It’s not just powerful processors or displays that matter — above all, it’s smart optics that make the difference. Devices must be lightweight, comfortable, and optically precise to deliver a realistic, dizziness-free user experience.

To achieve this, innovative companies need cutting-edge design and simulation tools, combined with a well-thought-out development strategy. For technology leaders, the message is clear: those who invest in AR/VR today will shape tomorrow’s market. FlexEnable impressively shows how smart optics and strategic simulation technology can generate real competitive benefits.

- Securing innovation speed: Simulation drastically shortens development cycles.

- Making technology manageable: Complex optical systems become plannable.

- Winning competition through R&D efficiency: Fewer prototypes, more impact.

- Positioning as a provider of key technology: FlexEnable delivers solutions that enable differentiation in the market.

Why Image Quality and Light Control Are Business-Critical

FlexEnable has developed a technology that can revolutionize AR/VR devices: ultra-thin, flexible liquid crystal lenses (LC lenses) that actively direct, modulate, and focus light. These lenses enable dynamic adjustment of image depth – a crucial factor for immersion. Only when virtual objects appear correctly focused in space does a believable impression arise. At the same time, the technology drastically reduces device weight – a plus for wearing comfort.

The LC lenses are based on optical plastic substrates (TAC, Triacetate Cellulose). With a thickness of less than 100 micrometers and a weight of a fraction of a gram, the LC lenses can also be stacked to increase focal length or integrate additional functions such as ambient dimming. This makes AR reliably usable even under changing light conditions.

Our Tip: Discover the Future of AR Optics

Download the full presentation by Daniel Jimmerskog from the CADFEM Conference and explore how FlexEnable is revolutionizing AR with tunable liquid crystal lenses and advanced simulation techniques.

Download the presentation

Simulation as a Strategic Gamechanger

What makes FlexEnable special is not just the hardware – but the path to it. Instead of relying on lengthy trial-and-error prototyping, the company uses simulation as a central development tool. With software solutions from Ansys – especially Zemax and Lumerical – optical designs are virtually tested, optimized, and validated before a physical prototype is even created.

Liquid crystals are naturally asymmetric. When multiple cells are stacked, a symmetrical system can be created in two layers. Through simulations and experiments, FlexEnable specialists discovered that the same type of properties can be generated in a single layer if the molecular orientations in different areas of the lens are optimized.

This allowed the necessary layers – and thus costs – to be reduced. At the same time, resulting haze effects in the optics were minimized and overall complexity reduced. To achieve this, FlexEnable engineers built a design optimization pipeline to simulate optical performance from various viewing angles. Consequently, the structure was optimized with Ansys Zemax so that a symmetrical lens profile emerged from the anisotropic liquid crystal environment. The result was a single-layer LC lens that also delivers good optical performance off-axis.

Pixelated ambient dimming enhances the visibility of virtual content in bright environments – a key to immersive AR experiences. | © Flexenable Technology Ltd.

From Idea to Product: Simulation as a Development Strategy

At FlexEnable, simulation is at the beginning of every product development. Simulations clarify what kind of design optimizations are needed and what changes lead to which behaviors. Only then are initial prototypes built. These also serve to validate simulation results. This approach not only saves time and money. It also increases the success rate of innovative ideas, as shown by the example of the aforementioned single-layer lens with different molecular orientations.

Zemax software forms the central foundation for a wide range of simulations and is consulted for various design evaluations. For example, it was also used to design the imaging part of an interferometer. This is now used by FlexEnable to evaluate the optical performance of lenses – both for imaging optics and illumination optics.

Partnerships as Innovation Drivers

A key success factor is close collaboration with technology partners such as CADFEM and Ansys. The interoperability of the simulation platform – for example through Python APIs – enables customized solutions and seamless integration into existing development environments. For manufacturers of AR/VR applications, this means: shorter time-to-market, lower risk, and higher innovation speed.

About FlexEnable

FlexEnable's award-winning technology enables flexible displays for consumer electronics and liquid crystal optics for AR/VR, privacy screens, and automotive smart windows. The company’s FlexiOM™ organic thin-film transistor (OTFT) materials together with its unique low-temperature process allow the use of bio-degradable plastic substrates instead of glass to make ultra-thin, ultra-light and conformable surfaces. With an established supply chain for OTFT production, FlexEnable has technology transfer programmes and mass production underway with several leading display manufacturers in Asia as well as commercial programmes with some of the world’s biggest brands in consumer electronics.

Watch now the interview with Daniel Jimmerskog (Senior Optical Design Engineer, FlexEnable):

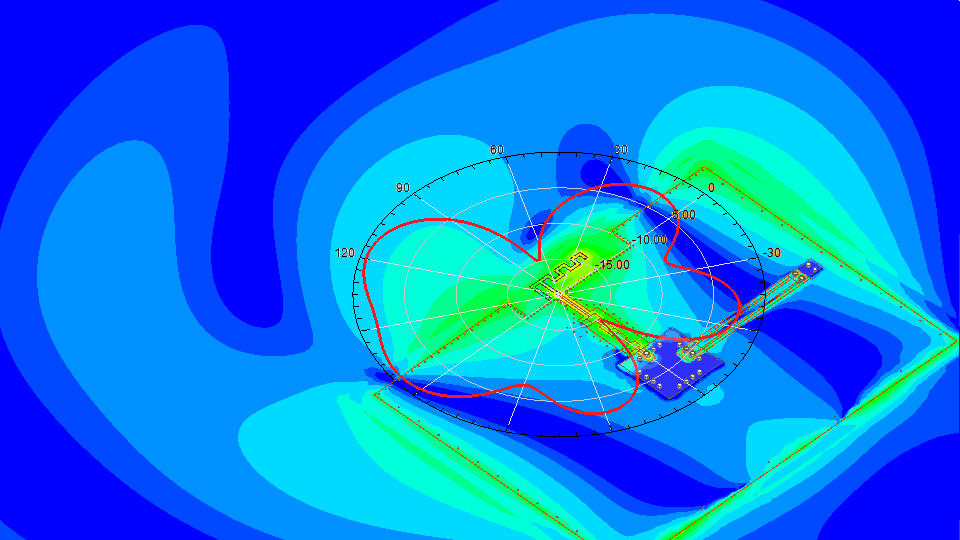

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.

FAQs

-

What makes FlexEnable’s liquid crystal lenses unique?

FlexEnable’s LC lenses are ultra-thin (<100 µm), flexible, and based on biodegradable plastic substrates (TAC). They enable dynamic image focusing and improve both wearing comfort and image quality in AR/VR applications.

-

Why is simulation essential for developing AR/VR optics?

Simulation shortens development cycles, reduces the need for physical prototypes, and enables precise design optimization. FlexEnable uses Ansys Zemax and Ansys Lumerical to virtually test and validate optical systems.

-

What benefits do LC lenses offer for immersive technologies?

They provide realistic depth perception, are lightweight and comfortable to wear, and perform reliably under changing light conditions—ideal for medical, automotive, industrial, and entertainment applications.

-

What is FlexiOM™ and OTFT?

FlexiOM™ is FlexEnable’s material platform for organic thin-film transistors (OTFT), based on flexible, eco-friendly substrates that replace glass—perfect for ultra-light AR/VR components.

-

How does simulation improve R&D efficiency?

Virtual testing and optimization reduce development risks, lower costs, and increase the success rate of innovative products—such as the single-layer LC lens with optimized molecular orientation.