From Finite Element Method to Data Management: Innovations through Simulation at PALFINGER

Johannes Raitmair

07.04.2025

Vision at technology leader PALFINGER: Replacing tests with simulation

Simulations are central to the entire development process. PALFINGER AG relies on simulation to evaluate ideas at an early stage and develop market-ready products. At the heart of every innovation is the customer. As a technology leader in crane and lifting solutions for the agricultural and marine industries, PALFINGER focuses on knowledge transfer and optimized processes. In an interview with Rupert Schweitl, Head of Static and Stability Calculation, learn how PALFINGER ensures efficient product development, minimizes physical testing, and creates more sustainable solutions.

Rupert, PALFINGER offers a very broad product range. You manufacture all kinds of lifting solutions—from loader cranes, aerial work platforms, and truck-mounted forklifts to hooklifts for recycling containers and high-performance offshore cranes. How important is Digital Engineering for you?

We started digitalizing our development process very early on. Initially, we worked only with CAD and ERP, but this has evolved significantly over time. Today, we fully integrate our products into dedicated systems to ensure seamless information exchange—from the product idea to development, production, and assembly to service. This comprehensive digital approach allows us to conduct simulations, further develop our products, and provide more sustainable solutions that offer real value to our customers.

Speaking of simulations: Would it even be possible for you to do without them?

No, simulations are essential to our entire development process. We started using them back in the 1980s, so we have a long history with them. At that time, we performed simple calculations to simulate deformations and stresses. Since around the year 2000, we have been using the Finite Element Method, and our simulation capabilities have continued to evolve—expanding to fluid dynamics and multi-body simulations, among others. Our vision is to replace as many physical tests as possible with simulations in product development. That’s why we strive to maximize the potential of our existing tools—helping us save prototypes, resources, and costs.

PALFINGER is a technology leader. How do you manage to stay so innovative?

Our driving force is always customer benefit. We see it as the top priority when developing a new product or improving an existing one. Since we use simulations very early in the process, our ideas are validated—or ruled out—right from the start. This allows us to learn a great deal and continuously improve.

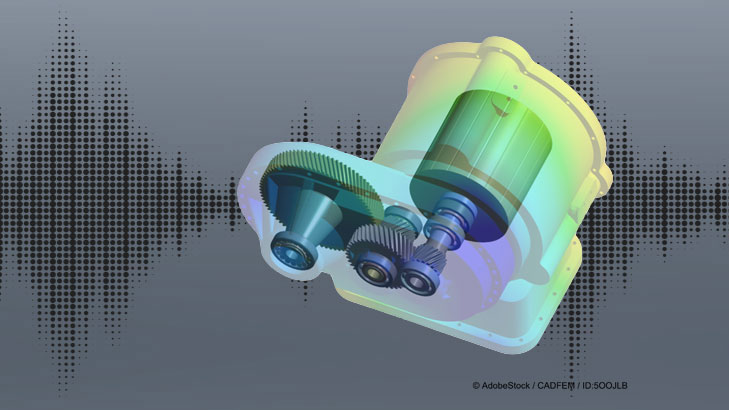

TIP: Reduce Your Computation Time in Ansys Mechanical!

Learn how to communicate effectively with Ansys Mechanical in “Let’s Simulate – Behind the Scenes of Ansys Mechanical” and cleverly reduce your computation time!

Can you give an example that demonstrates the significant impact of simulation in products from PALFINGER?

We mounted our most powerful crane on a standard-approved truck. With four axles, up to 32 tons are allowed without requiring a special permit, whereas five axles would need one. The big advantage for the customer is that they can use the equipment without any bureaucratic hurdles. That’s a major benefit—and this innovation was only made possible through simulation.

Simulations are central to our entire development process. Our vision is to replace physical tests in product development as much as possible with simulations.

How do you ensure the qualifications of your employees?

Training and education play a significant role at PALFINGER, as specific skills are sometimes required. In my area—stability and static calculations—we train our simulation experts on the specific tools they need for their work. We have a two-year training plan for them: a basic training program that lasts a year, followed by expert-level training.

For the simulations you and your team conduct, you need the appropriate hardware. How have you organized this?

We decided to use centralized computing servers. This way, we don’t need to place computers in every office, and we have much more computational power available to handle large calculations. Initially, it was a small challenge, but now it works well and provides us with immense value in terms of development speed.

Thank you for the conversation, Rupert.

Check out the full interview with Rupert Schweitl here: Watch the YouTube video

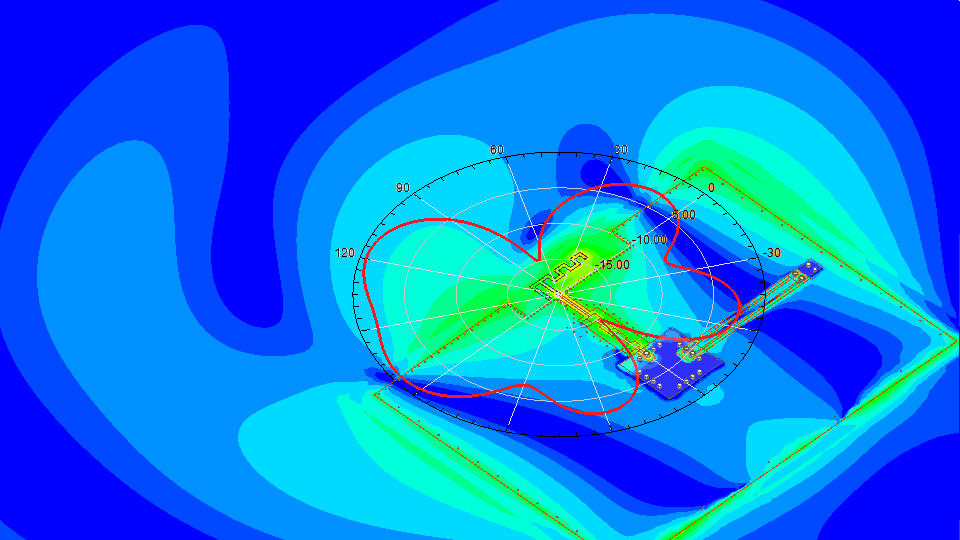

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.