PyAnsys: The Key to Workflow Automation

Manual processes often characterize the everyday work of Ansys Mechanical users in simulation and calculation. However, automation offers enormous ...

S'inscrire à la newsletter

Vous vous intéressez à la simulation numérique et souhaitez alimenter votre veille ? Inscrivez-vous dès maintenant.

Manual processes often characterize the everyday work of Ansys Mechanical users in simulation and calculation. However, automation offers enormous ...

What impact does hours of sunlight have on a steering wheel? I’ve “painfully analyzed” it myself in the Swiss summer: 70 °C on the surface. Thanks to ...

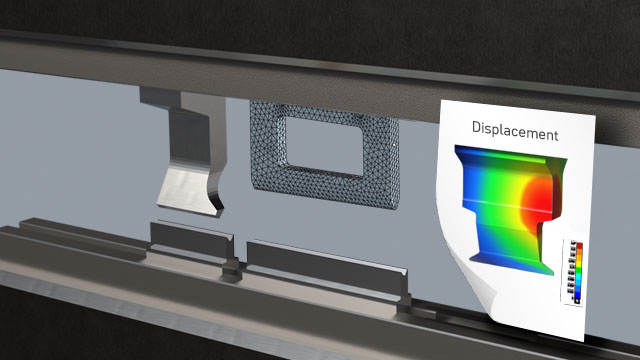

Unnecessarily rigid CAE workflows slow down simulation. When every geometry change triggers manual update loops to fix references, the process ...

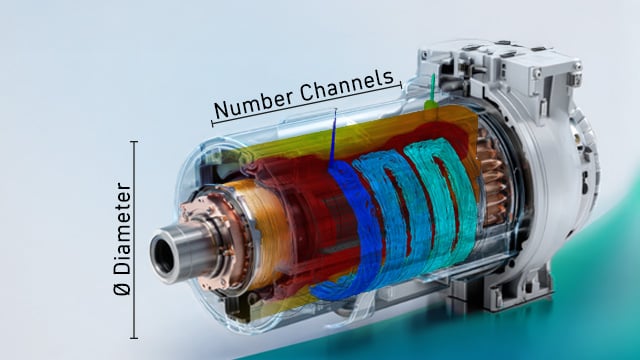

As product complexity increases, methods for process integration and design optimization are becoming increasingly important. Using the example of a ...

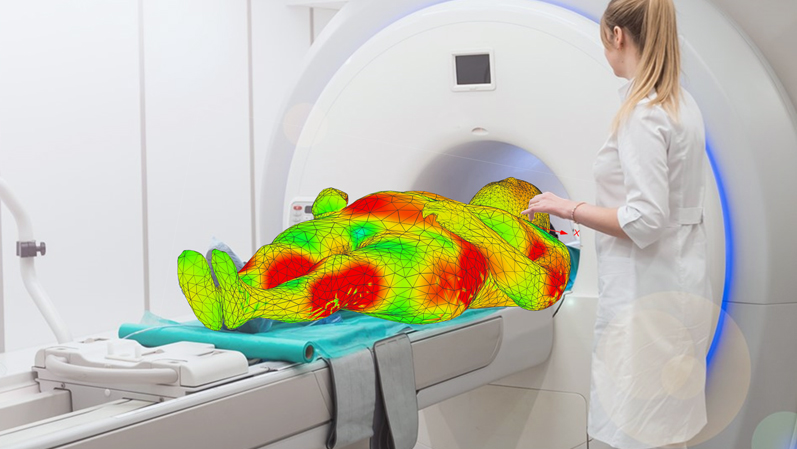

Magnetic resonance tomographs are now state of the art for diagnostic purposes in medical technology. However, the electromagnetic fields required ...

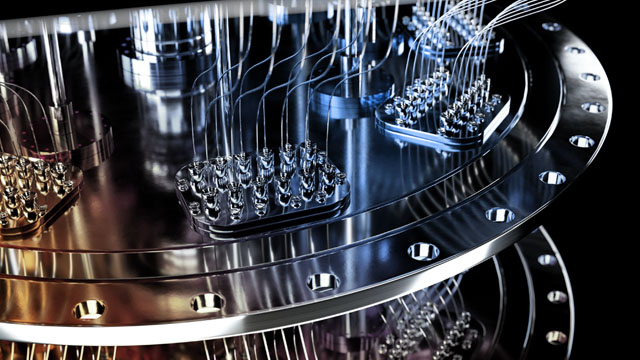

Since the mid-20th century, the global economy has relied on two key drivers: energy and computing power. Lots has been said about energy and green ...

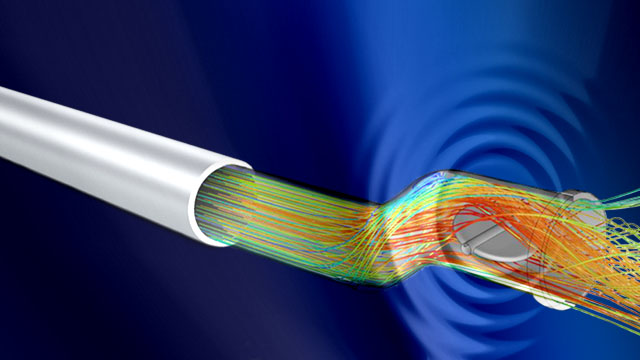

Wie entstehen Geräusche in Strömungen – und wo genau? In diesem Artikel geben wir Ihnen einen Überblick über die in Ansys Fluent verfügbaren ...

In bulk material simulations using the Discrete Element Method (DEM), precise calibration is essential. Since physical prototypes are often ...

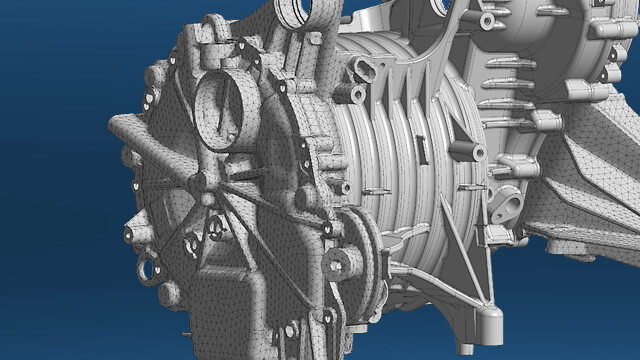

Meshing is a key step in the finite element method (FEM) for achieving accurate simulation results. From theoretical principles to practical ...

Are your components really as reliable as you think? An incorrect strength assessment can be quite costly. With the FKM guideline and Ansys, you can ...