Automation and AI in Engineering at GEMÜ

Alexander Kunz

14.10.2025

Verification of 2,000 Valve Bodies: A Case for Automation and AI

GEMÜ has over 2,000 metal valve bodies in its portfolio, and its pool of CAD geometries is correspondingly large. Each individual valve must be simulated to verify its load-bearing capacity in accordance with the Pressure Equipment Directive – a case for automation and AI, since it is faster and frees up employees from monotonous tasks.

© GEMÜ

GEMÜ Gebr. Müller Apparatebau GmbH & Co. KG is a leading manufacturer of valves, measuring and control systems for liquids, vapors, and gases. The family-owned company from Ingelfingen in Hohenlohe is active worldwide and stands for innovation and digitalization, and its commitment to providing its customers with exceptional added value.

Simulations have been an integral part of the development processes at GEMÜ for many years. Simulations are carried out using Ansys, and CADFEM is the partner for everything related to simulation. Since its introduction, the range of applications has grown continuously – both in terms of the physical domains and the way in which simulation is used.

The benefits of automation

A few years ago, GEMÜ began working with CADFEM to explore simulation automation with PyAnsys. The goal was to make processes more efficient, faster, and better. This is particularly suitable for recurring and standardizable tasks that simulation engineers see as a necessary evil because they leave them with less time for their demanding creative development tasks. That is why automation at GEMÜ is also seen as a contribution to greater employee satisfaction.

A load-bearing capacity test is required for metal valve bodies. | © GEMÜ

Automated stress analysis of valve bodies

Metal valve bodies are pressure-bearing components for which a strength analysis must be performed. GEMÜ offers customized solutions and has well over 2,000 variants in its product range, which is constantly growing. The required verification is performed using Ansys simulation software based on each individual CAD geometry, which is a tedious and repetitive process when done manually. However, these are ideal conditions for automation.

No sooner said than done: the development of an automated workflow was undertaken with CADFEM. In addition to the implementation of this specific project, the goal for GEMÜ in this collaboration was to transfer knowledge for future applications. One of the challenges with the valve bodies was that surface components and other metadata important for automation were not stored natively in the CAD data. Instead, they had to be derived from the valve body type, nominal diameter, and connection type. Their variance and lack of standardization are a particularly complex constellation, which meant that the purely script-based automation approach with PyAnsys ultimately delivered merely satisfactory results. Although these required considerably less effort than before, they still had to be manually post-processed.

GEMÜ must provide pressure equipment certificates for well over 2,000 metal valve bodies based on CAD geometries. | © GEMÜ

Simulate More Efficiently Through Automation

Automation proves its strengths especially where processes or subtasks are performed regularly or where high precision is required. Learn more about the benefits, approach, and use cases in the factsheet.

Download Factsheet (in German)

Workflow optimization with AI

This example shows how AI can complement and optimize simulation automation, especially for complex tasks. With the STOCHOS AI solution from CADFEM partner PI Probaligence, it was subsequently possible to completely automate the entire workflow – geometry preparation, modeling, standard-compliant evaluation according to the Pressure Equipment Directive, and reporting – and, most importantly, to significantly improve the quality of the results. The decisive factor was a machine learning model trained by STOCHOS using geometry-based metadata, which reliably processes the most diverse properties of CAD geometries and recognizes pressurized surfaces as well as inlet and outlet surfaces with almost 100% accuracy. These surfaces then serve directly as the basis for the further automated model construction of the non-parametric (“dead”) geometries with PyAnsys.

It is important for simulation automation that surfaces can be classified using the STOCHOS AI solution and clearly assigned to functional faces. | © GEMÜ

I believe that anything that can be sensibly automated should be automated. This allows experts to concentrate on exciting cases and explore new fields of application.

Scaling

The automation solution is already in use at GEMÜ and is reducing the workload of the simulation engineers. However, development is far from complete. In fact, this is just the beginning. In addition to the newly acquired expertise, individual modules can also be used in other automation applications.

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

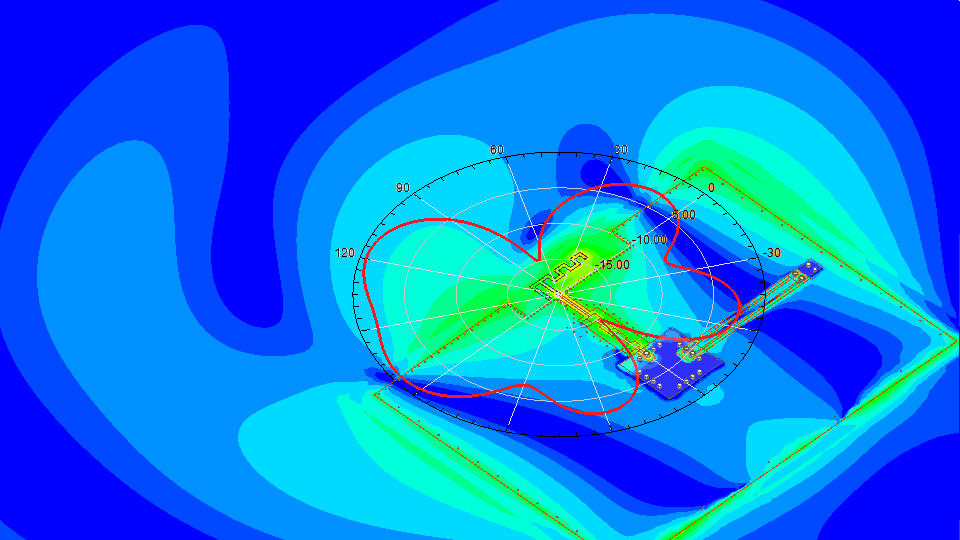

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.