Material Data Management for Compliance and Digital Product Passports: Proactively Meeting Requirements

Marc Vidal

02.12.2025

Reliably meet regulatory requirements and create a foundation for sustainable business models

Increasing material compliance requirements and the Digital Product Passport (DPP) present companies with complex tasks. Data must be systematically analyzed, maintained, and communicated throughout the entire product lifecycle. A parts list-based and integrated approach enables early risk analysis and automated verification processes, forming the basis for sustainable, digital business models.

Regulatory requirements for products and their materials are continuously increasing – both in breadth and depth. In addition to established regulations such as REACH or RoHS, new requirements are coming into focus, e.g. regarding PFAS or obligations and opportunities related to the Digital Product Passport (DPP).

This entire legal framework presents companies with the challenge of recording and providing material and process data completely, consistently, and traceably throughout the entire product lifecycle – from development through manufacturing to market release and end-of-life considerations. In addition to potentially significant fines, sanctions such as sales bans for certain markets and reputational damage may occur.

Material Compliance without a System: Reactive Processes and High Risks

In many companies, material compliance requirements are still met using Excel spreadsheets, manual checks, and person-dependent knowledge. Instead of active management accompanying development, evaluation takes place at the end. If the result is negative, development loops must be repeated, as alternative materials also bring changes in function and cost. Due to the distributed storage of data and manual maintenance, this process is exposed to an uncontrollable risk of error.

This approach is not only time-consuming but also error-prone and risky – especially in the face of regulatory changes and personnel turnover. If products are sold in various international markets, the effort and associated error risk multiply.

Digital Product Passport (DPP): A Driver for Sustainable Product Development and Compliance

The DPP requires the structured provision of information such as:

-

CO₂ footprint

-

Material composition

-

Recycled content

-

Repairability

-

End-of-life considerations

These data must not only exist but also be systematically maintained and communicable across the supply chain. Although the DPP will only become mandatory in many industries in the coming years, there is already a need to develop strategies for how the necessary architecture can be provided.

However, the DPP is not only a driver for establishing a consistent data structure for compliance and material knowledge. It is already a highly interesting medium for many companies to build customer access by offering digital services targeted to the customer via the DPP QR code on the product. For these reasons, there is already great interest in identifying the building blocks that help pave the way to the DPP as robustly as possible.

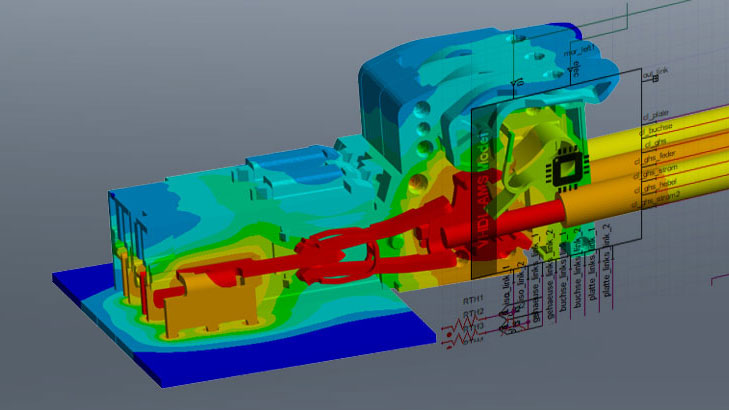

Compliance check of the Bill of Materials for regulated substances. | © CADFEM Germany GmbH

Automated Material Compliance with Ansys Granta: BOM-based, integrated into the development process, and proactive

An ideal approach to material compliance is bill-of-materials-based and integrated into the development process. This allows risk to be proactively managed from the outset and provides fast and reliable reporting capabilities at every stage of development. An integrated approach of this kind automatically delivers the data relevant to the DPP regarding materials.

A systematic approach to material compliance is based on the following principles:

- Early assessment of compliance risks based on BOMs and material definitions.

-

Management of in-house data together with reference data for a comprehensive view of material knowledge relevant to the company.

-

Curated rule set with current international regulations and watchlists.

-

Automated checking mechanisms that connect with existing PLM/CAD/CAE systems.

-

Automation capability for DPP projects.

-

Transparent decision-making basis for engineering, purchasing, production, compliance, and management.

With a solution like Ansys Granta, these principles can be implemented in practice. Since Ansys Granta integrates into the development process and system landscape, all stakeholders benefit from consistent data, automation capability, and reliability.

Moreover, it is possible to estimate early in development which variants will be compliant at the time of market launch. It is equally important to identify alternatives early and to evaluate the resulting design variants in terms of their functionality using simulation.

Instead of reactive reporting, proactive risk management is enabled – up to a design for cost, function & compliance.

Benefits for Companies

-

Security: Reliably meet regulatory requirements – today and at market launch

-

Efficiency: Reduce manual effort and sources of error

-

Transparency: Clear view of risks, need for action, and alternatives

-

Future viability: Foundation for digital services and sustainable business models

-

Risk analysis: proactive and early in the development process

Implementing DPP Integration: A Three-Step Approach

We actively support our customers on this journey. The fundamental challenges may be similar, but the respective priorities are individual. Therefore, the following approach has proven effective:

- Exploratory discussion – goal definition, status quo analysis, clarification of expectations

- Workshop – assessment of theinitial situation, business case, solution outline, budget framework

- Pilot project – implementation focusing on relevant use cases, scalability, and integration

FAQs

-

What is the Digital Product Passport (DPP) and why is it becoming relevant?

The DPP is a structured data set that collects and provides all key information about a product throughout its entire lifecycle. This includes details such as CO₂ footprint, material composition, and recycled content. It is gradually becoming mandatory and creates transparency across the supply chain. At the same time, the DPP opens the door to new digital service offerings.

-

What are the risks of manual material compliance?

Manual processes using Excel spreadsheets are error-prone, time-consuming, and often only come into play at the very end of the development process. Negative results at that stage lead to costly iterations. For companies operating internationally, the effort and risk increase even further.

-

How does a BOM-based, development-integrated approach support DPP and material compliance projects?

Risk management becomes proactive rather than reactive. An integrated approach enables compliance checks and the identification of alternatives directly during development. Data remains consistent, saving time and money while enabling automation to provide relevant DPP data quickly, securely, and up to date.

-

How can compliance data be maintained consistently throughout the product lifecycle?

Ansys Granta manages all material knowledge within a company in a consistent, traceable, and comprehensive way. Key factors include centralized data management, sustainability indicators, substances and current regulations, as well as integration capabilities with PLM, CAD, and CAE systems.

-

What strategic opportunities does the DPP offer beyond compliance?

The DPP is more than a mandatory requirement. It strengthens market positioning by emphasizing and communicating sustainability. It enables digital services via QR codes and becomes a direct communication channel to customers. Companies that start early secure a competitive advantage.

-

What does a typical implementation process look like?

Getting started with Ansys Granta can be achieved in a very short time. A step-by-step approach is recommended for deep integration into existing development processes: gather stakeholder requirements, map cross-functional workflows, and support implementation throughout the process.

Further Resources

-

Seminar "Systematic Selection of Materials using Ansys Granta Selector"

Learn how to derive material properties from product requirements and how to find suitable materials in a structured and reliable way. This training is offered as a 1-day course.