How WAGO uses reduced order models to simplify simulation processes

Alexander Kunz

28.10.2025

ROMs relieve engineers and deliver fast simulation results

If only a small amount of information is relevant in 3D FEM models with 1 million degrees of freedom, it can be exported to small, reduced order models (ROMs). This saves a lot of time. An example from WAGO shows how this works in Ansys, with many parties benefiting: Simulation engineers and sales staff at WAGO are unloaded of a huge burden because customers can evaluate connectors themselves using thermoelectric simulations.

© WAGO

“We were faced with the challenge that our small simulation department had to deal with an increasing number of inquiries from customers and colleagues in sales and product management in addition to product development,” says Wilhelm Rust, simulation engineer at WAGO, describing the trigger for a groundbreaking project. This is because even internal simulation-as-a-service offerings are based on large 3D FEM models and are therefore computationally intensive. This quickly added up to two weeks of processing time.

The solution in three steps:

- The simulation team knew where to start - with the model sizes. Because the team also knew that many customers had very similar questions, a reduced model with the electrothermal properties relevant to the customer is now exported from every finished 3D FEM model.

- This can be easily used for the thermo-electrical evaluation of connectors and terminals – by the product manager, technical support or the customer themselves. Existing simulation knowledge is used at another point in the product life cycle: at the interface to the individual customer application.

- The WAGO team took this one step further. The model was further automated, trained, and integrated online in the e-shop. Today, customers can check the suitability of parts completely independently, 24/7, and with just a few clicks.

Detailed look: Ansys models in the web shop – how does it work?

As easy and intuitive as the Ansys models are to use online today, their journey from the calculation department to the e-shop was rocky. With this project, WAGO was breaking new ground, both internally and within the industry. “We started out in an exploratory manner,” says Wilhelm Rust, describing the approach. “At the beginning, we didn't really know how everything would work.”

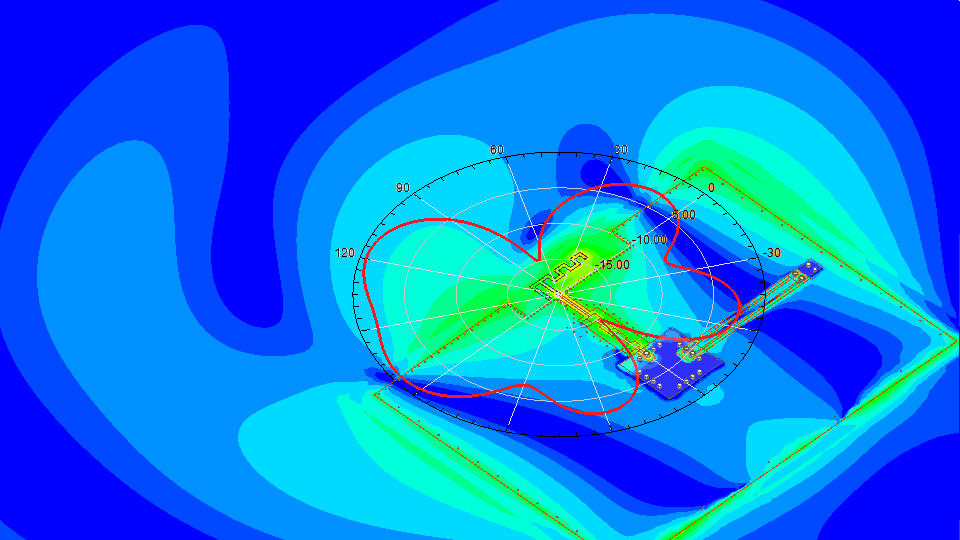

3D FEM model of a connector in WAGO: Detailed, but large and computationally intensive. | © WAGO

How does a 3D FEM model become a 1D reduced order model?

For the simulation specialists, the main challenge was to export a suitable reduced model from the 3D FEM model. In consultation with CADFEM, the specialized software “Model Reduction inside Ansys” emerged as the solution that would help WAGO, including training, instruction, and support.

Get to know MOR inside Ansys and try it for free

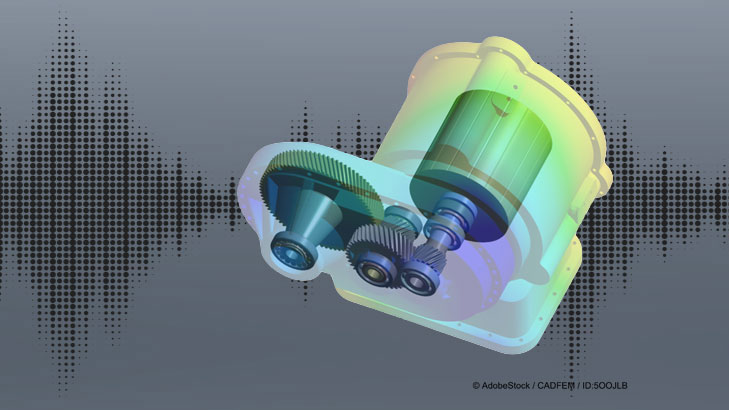

Skalierbare Reduzierung komplexer 3D-FEM-Modelle mit Model Reduction inside Ansys.

What role does CADFEM's MORiA play in the creation of thermoelectric reduced order models?

Model Reduction inside Ansys (“MORiA”) is particularly suitable for thermal, mechanical, and thermomechanical tasks. MORiA, which was developed by CADFEM in cooperation with the Steinbeis Transfer Center Lower Saxony, uses highly efficient Krylov-based model order reduction in conjunction with a reduction approach from electrical engineering that uses the inputs and outputs of the system and picks up on their relationship, the transfer function. With MORiA, the usual 1 million degrees of freedom of thermomechanical, thermoelectric, or piezoelectric models in Ansys Mechanical can be automatically reduced to the crucial 100 and used in system simulations. An APDL workflow gives the user full control over the reduction.

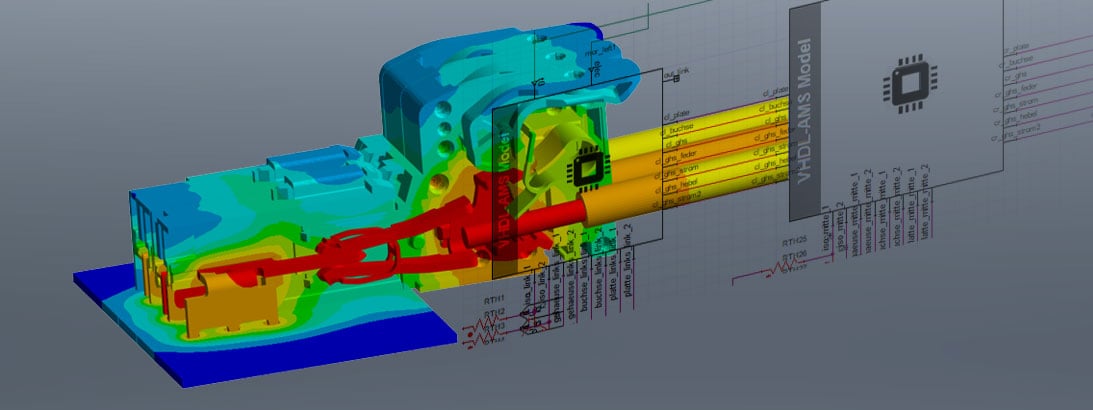

Reduced order model of the electrical-thermal properties that are crucial for connectivity. | © WAGO

Thanks to the workflow developed with CADFEM, MORiA now has a firm place in WAGO's development process for connectors and terminals. “By exporting the parameters relevant to the customer to a 1D ROM, we can share the results of our work with customers immediately and with little effort,” says Wilhelm Rust. Since ROM models do not allow any conclusions to be drawn about the original complete models, there are no restrictions with regard to IP and data protection issues.

Which thermal properties are decisive for the reduced order models at WAGO?

Back to the application: For WAGO customers, the thermal heating of electrical connectors and PCB terminals is important. It must remain below defined limits under the specific dynamic load profiles acting in their systems, i.e., current and ambient temperature, and this in as small a design space as possible. Consequently, the respective ROM contains the information that is crucial for this.

Intuitive solutions with Ansys TwinBuilder and machine learning

With Ansys TwinBuilder, the ROM is implemented in an overall context, i.e., a large number of dynamic load profiles are simulated in a short time. This allows many different current loads and changing ambient temperatures to be evaluated manually.

It is even more convenient for customers if they can check the suitability of WAGO products quickly and independently at any time. “All the more so,” says Wilhelm Rust, “because these are components that do not play a major role in electrical systems. Anyone who wants to configure a wall box or an inverter does not want to spend ages dealing with the conductor connection.”

The models were trained using machine learning so that they can also be used online in the e-shop by customers to evaluate and identify the right product. WAGO started with 10 products. “We were able to generate a total of 20,000 data sets for these products in different variants. This is a very good basis for training the neural network, from which we have already been able to extract further variants,” says Wilhelm Rust, explaining this supposedly final step.

By exporting the relevant parameters to a 1D ROM, we enable customers to benefit directly and with minimal effort from the results of our work.

How were the reduced order models for the e-shop integrated?

Even with “supposed” trained models, the goal had not yet been fully achieved. Wilhelm Rust: “Once you have developed and trained the machine learning model for online use, it must of course also be made available. This means that IT has to check everything and integrate it into its systems. And then there’s the website: design, data maintenance—all things that engineers tend to underestimate.”

In spring 2025, the portal with the e-shop was finally launched, featuring the 10 products from the first phase. More will follow quickly, because WAGO now has a functioning workflow.

This gives WAGO a unique selling point in the industry, and the company is eagerly awaiting the market response. Wilhelm Rust: “It now has to be integrated into our customers' planning processes. They were used to data sheets, but we are very optimistic that this new option, which was ultimately initiated by our simulation engineers and relieves us of a great deal of work, will become established.”

Simulations based on reduced order models of products in the WAGO e-shop make configuration and selection easier for customers. | © WAGO

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.