How WAGO benefits from simulation across departments

Alexander Kunz

10.12.2025

The broad spectrum of simulation in electrical interconnection technology

Around 20 years ago, WAGO, the specialist in electrical interconnection technology, introduced simulation in its R&D department. We spoke with Dr. Wilhelm Rust from WAGO’s 10-member simulation team: a conversation about technical challenges, creativity, and the journey from a niche topic to an integral part of cutting-edge digital engineering processes.

Dr. Rust, what was the topic of your presentation at the CADFEM Conference?

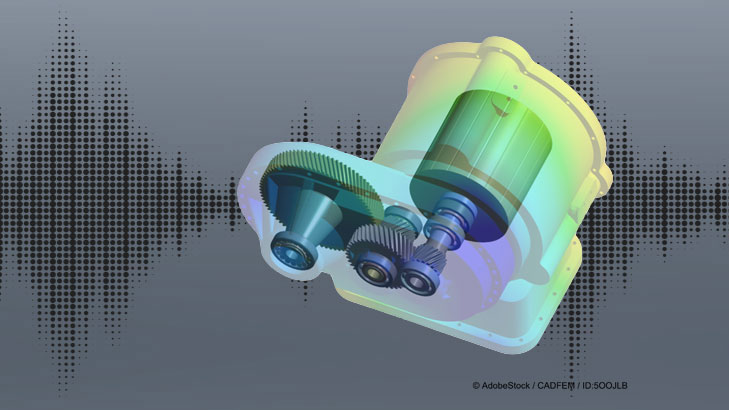

The focus of my presentation was the modeling of contact resistance. It deals with electromechanical processes that occur during the electrical transmission of moving contacts. Here, we are dealing with a conductance that depends on pressure and can therefore vary significantly. Surface properties, material pairings, and environmental conditions also play a role. We programmed these relationships as a subroutine in Ansys, so the simulation provides quick answers for many scenarios that are relevant to us.

Contact resistance model for electromechanical simulation | © WAGO

How is simulation generally organized at WAGO?

As a simulation department, we belong to Research & Development and support other departments at WAGO with our services: for example, early-stage development during initial design, the design team when clarifying strength issues, and our lab in achieving the goal of “First Time Right.” These colleagues want to focus entirely on final approval and product verification. All preceding analyses – keyword: variant studies – ideally take place with us on the virtual model.

Why is the “First Time Right” approach so important?

In the past, development processes relied heavily on experience and experiments, which worked well. In 2005, WAGO introduced simulation, and gradually the path to the finished product involved iterations between the lab and simulation. Problems were increasingly identified and solved on the digital model. The more detailed the models, the more precisely we could act. Now we have reached First Time Right – fortunately, because otherwise the many different products driven by the energy and mobility transition and the trend toward miniaturization would be impossible to manage.

In the past, development processes relied heavily on experience and experiments. In 2005, WAGO introduced simulation. Now we have reached First Time Right – fortunately, because otherwise the many different products driven by the energy and mobility transition and the trend toward miniaturization would be impossible to manage.

So with simulations you can perfectly support your colleagues in adjacent technical departments. What about other areas – are there touchpoints there as well?

Absolutely. You see, our products are highly standardized. Differences, issues, and added value lie in the details, and our colleagues have understood that simulations uncover them. When we provide automation, for example through reduced models, others can use them too – even sales or the customer themselves – as a simulation routine as a service.

Digitalization at WAGO is clearly in full swing …

Exactly. The vast amount of data we have generated and continue to generate is a real treasure. Think of AI applications that rely on it or precise digital twins of our products. Our long-standing CTO Karsten Stoll drove digital engineering forward early on, which is evident not only in the data-driven product development described but also in our involvement in the Industrial Digital Twin Association (IDTA).

Karsten Stoll, former CTO of WAGO Interconnection

Three Questions for Karsten Stoll, former CTO of WAGO Interconnection:

How WAGO addresses technological change, globalization, and digitalization.

So you’re in exactly the right place here at the CADFEM Conference!

You can see here that many colleagues from other companies face similar challenges. Many approaches are not entirely new but are only now reaching industry after being discussed and prepared mainly in academia. Somehow, we’re all thinking in the same direction and are pleased that simulation has left its niche and become a driver of digital engineering.

Watch the full interview with Dr. Wilhelm Rust now on our YouTube channel! Full video