The Digital Bike Lab - Automation of Bicycle Frame Structural Analysis

Christophe Ozier-Lafontaine

08.05.2025

How bike complexity pushed Radiate to automate the structural analysis workflows

Radiate Engineering & Design AG is a Swiss engineering firm combining simulation and prototyping to deliver innovative, reliable designs for bikes, civil UAVs, and more. Founded in 2015, based in Zurich. To improve efficiency, reduce the time required for structural analyses, increase consistency, and respond more quickly to customer requests, Radiate needed to create a scalable process.

Juan Navarro, Radiate's lead engineer for conducting structural analyses (FEA) for bicycle frames | © Radiate Engineering & Design AG

With a unique approach, Radiate integrates simulation-driven engineering with hands-on prototyping and testing allowing rapid iteration and validation of concepts. This ensures that products are both innovative and reliable.

Facing new challenges

The increasing complexity of modern bike frames (especially E-Bikes) and the demand for quick iteration cycles, along with further cross-functional collaboration between simulation experts and design engineers, rendered the usual workflow inefficient. Indeed, Radiate found the traditional manual process of conducting structural analyses (FEA) for bicycle frames time-consuming, error-prone, with a lack of consistency, leading to extended development cycles.

To overcome these challenges, Radiate decided to create a reliable and repeatable process that would streamline FEA execution, reduce the possibility of human error, and accelerate the design-to-verification timeline by involving simulation experts and design engineers in cross-functional collaboration.

Physical prototype of the MTB frame made out of AL606 that was used as an example in the automation process | © Radiate Engineering & Design AG

Automating the frame engineering workflow with Radiate’s digital bike lab

The solution, which Radiate now calls the "Digital Bike Lab", was the development of a fully automated simulation workflow using Ansys Discovery and Ansys Mechanical. This includes a parametric geometry preprocessing, loadcase generation tailored to the exact requirements for the application, automation of the simulation set up (contact definition, mesh controls, boundary conditions, etc.) and most crucially an automation of the postprocessing of the simulation results with state of the art knowledge in fatigue analysis. Expectations were exceeded by not only achieving reliable and fast simulations, but also offering a scalable approach for diverse bike frame types.

The automated workflow reduced the time to complete a structural analysis from several days of work to a few hours. Frame design iterations became significantly faster and more reliable, reducing manual errors. The ability to analyze more design variants in a shorter period led to better-informed decisions and higher quality outcomes. Internal users reported appreciation for the consistency and visualization clarity of the results.

Workflow 1: ensures that the contact definition is done in seconds and that it remains stable upon design iterations contributing to a lot of time savings when exploring different designs.

Workflow 2: the load cases are automatically generated. Thanks to the fact that this is scripted within the custom extension that Radiate has developed for Ansys Workbench, all the previously processed steps are visible to this workflow so the load cases are automatically tailored to the specific needs for each frame analysis.

Ultimately, Radiate saw improvements in simulation quality, reduced turnaround times, and cost savings, reducing reliance on manual labor and iterative physical testing.

- Faster design iterations,

- Reduce manual errors,

- Deliver higher quality insights

- Optimize product development

Discover more on automatization of worklows and collaboration

This webinar emphasizes on workflow, automation and simulation apps, with Ansys. Extend simulation benefits beyond R&D to production, sales, and service. They share valuable simulation insights without technical knowledge.

Engineering the next ride: Radiate’s simulation journey with CADFEM and Ansys

The implementation of the Digital Bike Lab was supported through a ¨Guided Work ¨ with CADFEM, which included technical advice and joint model reviews. Thanks to this collaboration the custom python scripts that encapsulate the logic for the automation of the process were refined to ensure maintainability and efficiency. Their ¨Guided Work ¨ support included hands-on guidance for model improvements, boundary condition setup, and optimization of simulation strategies. CADFEM also provided validation feedback on model setups and reviewed results together with Radiate. Their expertise in Ansys and simulation workflows was instrumental to the project’s success.

Future cooperation with CADFEM could include high-performance computing integration, additional automation, and ongoing software training. The bicycle frame workflow project is a prime example of Ansys's impact on innovation, efficiency, and product quality at Radiate. Radiate plans to expand the workflow to include even more advanced analysis scenarios and frame configurations.

With Ansys as a central simulation platform, Radiate sees opportunities for more data-driven development processes and enhanced digital twin applications - be it for customers from the bicycle industry or for customers from other industries.

The Digital Bike Lab: Radiate's development approach and could become the gold-standard for the bicycle industry | © Radiate Engineering & Design AG

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

Request for a free meeting

CADFEM engineers have extensive experience of implementing digital engineering tools in a wide range of industrial sectors. They will work closely with you to define the most appropriate solutions.

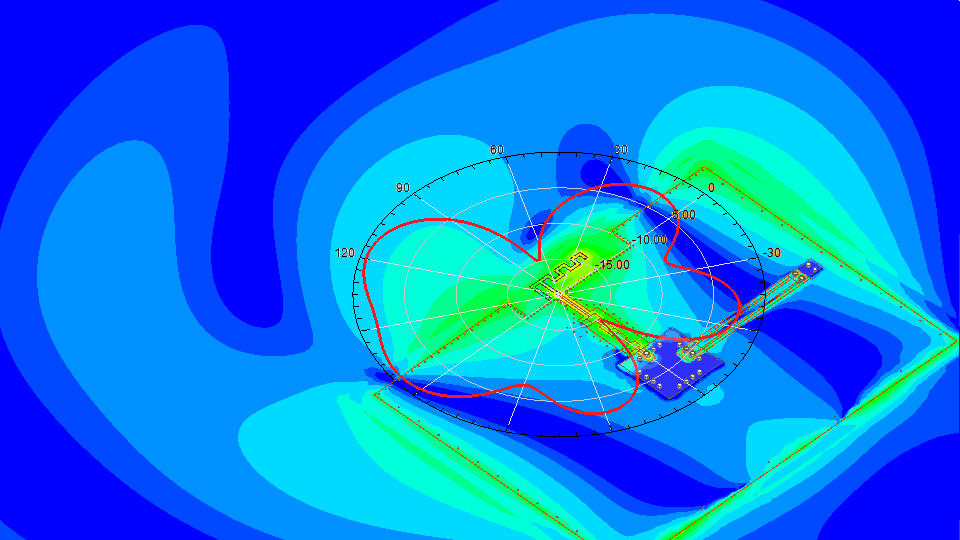

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.

Co-Author

Frederic Poppenhäger

Radiate Engineering & Design AG

+41 (0) 44 521 63 75

poppenhaeger@radiate.ch

Co-Author

Christophe Ozier-Lafontaine

CADFEM (Suisse) AG

+41 (0)21 614 80 48

christophe.ozier-lafontaine@cadfem.ch