Simulation of a thermal network model for lighting system drivers

Frank Weiand

15.05.2025

Accelerated thermal simulations that closely match the CFD model

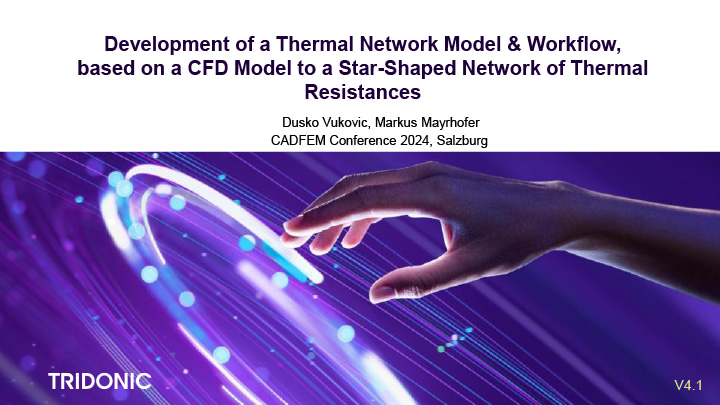

Markus Mayrhofer and Dusko Vukovic (Tridonic GmbH & Co KG) have found a way to create more streamlined models for thermal simulations. They gave a presentation on their work at the CADFEM Conference in Salzburg. We talked to them about highly detailed meshing, the development process and the benefits of simulations.

Markus, Dusko, you have been working on the development of a thermal network model based on a CFD model. What problem did you want to solve with the project?

Markus Mayrhofer: We work for Tridonic, a world leader in lighting technology and a member of the Zumtobel Group. Thermal simulations are essential for every electronic product we develop there. Our simulation models are generally very detailed and therefore have very fine meshes. The problem is that they are far too extensive to be integrated into larger systems such as the “luminaire” system. That's why we were looking for a simplified thermal model. It should lead to shorter simulation times, be useful even in geometrically larger models, and deliver results that are as realistic as possible and closely match the CFD model.

We want to know how long devices will remain operational and whether their life cycle can be extended. With our model, we can predict whether a device may need to be replaced soon, which can be an additional service for the customer.

How did you come up with the idea?

Dusko Vukovic: It was an EU-funded project. The aim was to develop an intelligent digital twin for a complete lighting system – including LED modules, controls and drivers. We worked on the driver.

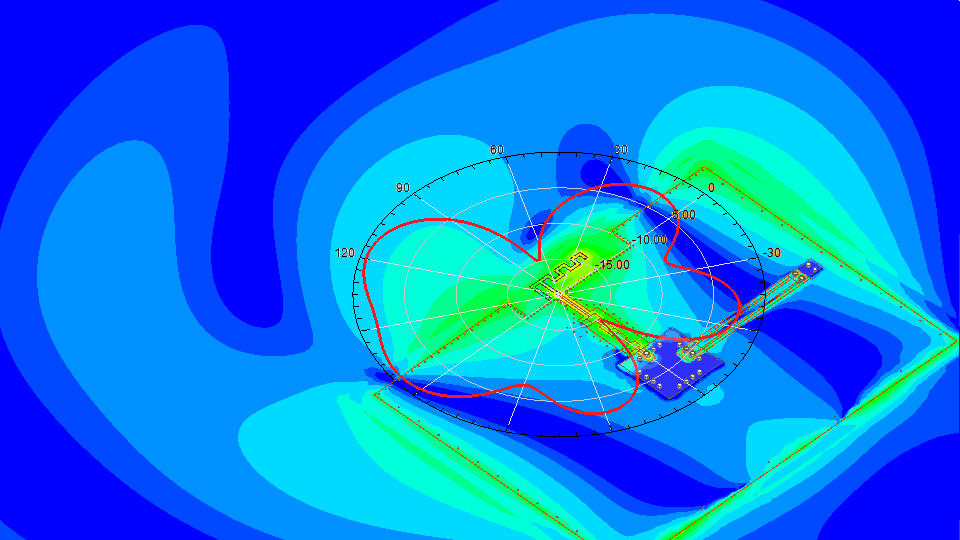

Improved thermal resistance network model | © Markus Mayrhofer, Tridonic GmbH & Co KG

Vorstellung von NeMo.bil am 11. Juli 2024 in Paderborn: Robert Habeck nimmt mit INYO Geschäftsführer Marcus Zwick (links) Platz im INYO CAB | © Besim Mazhiqi

Im Rahmen des vom Bundesministerium für Wirtschaft und Klimaschutz geförderten Innovationsprojekts NeMo.bil entsteht mit dem INYO CAB ein intelligentes, vollelektrisches Fahrzeug für den urbanen und suburbanen Raum. Entwickelt von der INYO Mobility GmbH, einem Unternehmen der CADFEM Group, bietet der futuristische Viersitzer adaptive Einsatzmöglichkeiten – als autonomes Einzelfahrzeug oder im synchronisierten Konvoi.

What challenges did you face during development?

Dusko Vukovic: Development took about six to eight months from the modeling of the CFD-based driver to the thermal network model. Initially, we had difficulties with the mesh settings of the printed circuit board, since it is only 35 micrometers thick and requires a fine resolution. Another challenge was determining the heat flow of the driver electronics. Through an iterative process – with many simulations and measurements – we were finally able to create a reliable network model. Apart from the technology, we also found it exciting to work together with different departments at our company and at the European level. This allowed us to immerse ourselves in other worlds.

Presentation by Markus Mayrhofer and Dusko Vukovi

Learn more about the topic ‘Development of the Thermal Network Model Based on a CFD Model to a Star-Shaped Network of Thermal Resistances’ and download the presentation by Markus Mayrhofer and Dusko Vukovic (Tridonic GmbH & Co KG)

Download now!

What added value does this project have for Tridonic, Zumtobel and its customers?

Dusko Vukovic: For example, we have developed a workflow to determine the heat flows and temperatures that we need to calculate the thermal resistances. We can now apply this workflow to all kinds of drivers.

Markus Mayrhofer: In the future, our customers will be able to insert a driver into a luminaire faster and easier. The product will therefore reach the market sooner. Another motivation was to monitor how long devices can be used and whether their life cycle can be extended. Nowadays, there is a constant demand for longer guarantees. It is important to know whether or not the device has exceeded certain temperature limits over a long period of time. With our model, we can predict, among other things, whether the device may need to be replaced soon. This can be an additional service for the customer.

How important is simulation in your company in general?

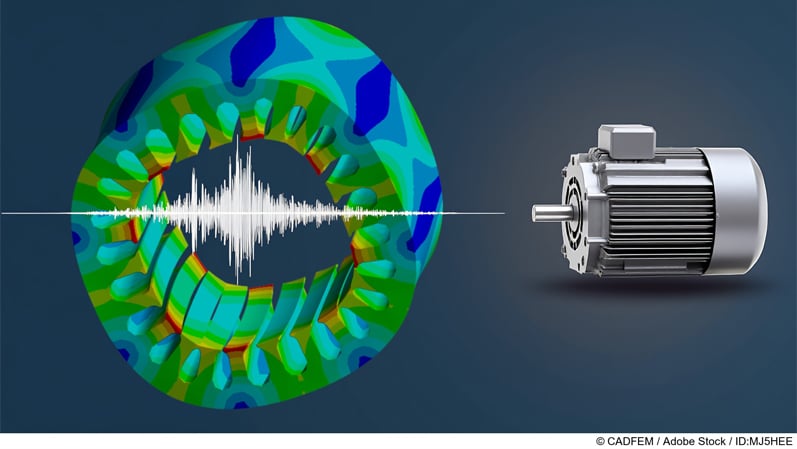

Markus Mayrhofer: Simulation has a very long tradition at our company, going back 20 to 30 years. It started with electronic simulations. Later, thermal and magnetic simulations were added, followed by the simulation of wireless systems, in particular antenna and wave propagation. The next step is to develop systems using artificial intelligence.

Dusko, Markus, thank you very much for the interview.

Watch the full interview with Dusko Vukovic and Markus Mayrhofer here:

Optical simulation

Precision & efficiency combined. Find out in our webinars and further information how you can develop your optical designs with maximum precision.

Ansys Startup Program: simulation for startups

Take advantage of the best in simulation technology, right from the start of your business, with a reduced investment.

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.