The path to the optimal variant: Shorter development cycles with parametric models

Gerhard Friederici

19.08.2025

BSH optimizes ovens with expert task force, parametric models, and AI

With over 75% time savings in product development and significantly better results, a project by BSH, CADFEM, and the University of Trieste shows how parametric models and AI can transform product development. The task: optimizing the laser welding process for oven housings. The result: a transferable framework for faster, more robust product development. In a conversation with Dr. Piero Favaretti (Senior Development Engineer, BSH Hausgeräte GmbH), you’ll learn how simulation expertise and AI can shorten your innovation cycles—and how you can benefit from it.

Schalter sind standardisierte Serienprodukte. Das beschriebene Projekt wurde am Schaltwerk des Modells 506U durchgeführt | © JUNG

Mr. Favaretti, what was the project about?

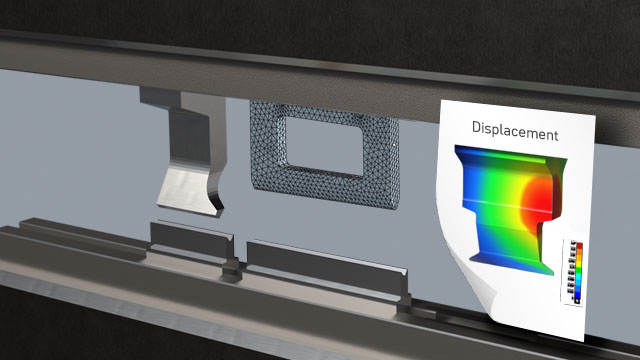

The outer shell of an oven was to be joined by a large number of weld spots without the metal sheets warping too much. To achieve this, BSH, in collaboration with CADFEM and the University of Trieste, developed an innovative, robust, and efficient method for simulating and optimizing the laser welding process. The main goal of the project was to minimize the residual stresses in the housing sheets and the resulting deformations after the welding process. For the simulation of the pulsed welding process, a parametrizable moving heat source was developed.

Case of two welded metal sheets losing their planarity | © BSH Hausgeräte GmbH

What tasks did you take on in this project?

When I first became involved in discussions about this project, numerous experimental trials had already been carried out. However, the test results achieved up to that point were still unsatisfactory. Therefore, I was asked to use simulation to find the optimal process parameters to minimize deformations—while of course ensuring sufficient bonding strength.

What preliminary work had already been done and what strategy did you pursue?

My colleagues had already conducted many experimental tests but still couldn’t avoid the deformations. Consequently, it was clear to all involved that there was still great optimization potential that could be unlocked through simulation.

Since I had no experience in modeling the welding process, I first built a task force team to gather the key competencies.

To reach our goal as quickly as possible, I also involved CADFEM—mainly to support us in creating simulation models with Ansys. But we also wanted to leverage the extensive expertise of CADFEM specialists for the optimization, which was carried out using Ansys optiSLang as the base platform.

Additionally, the University of Trieste contributed its optimization know-how based on advanced machine learning methods.

Details, tips and tricks

Learn more about "Parametrizable moving heat source for pulsed welding simulations" and download the presentation by Dr. Piero Favaretti. (Note: Slides are in German)

Download here for free

Can you briefly describe the market situation for kitchen appliance manufacturers

We are currently experiencing years of intensified competition, and to remain competitive, we naturally have to reduce costs. But I find it even more important that we bring innovations to market quickly. These two goals can only be achieved through intensive use of high-quality simulations.

Moreover, we simulation experts have the reputation of being general technology experts, including topics like AI. Thanks to the spread of AI, I currently see a conceptual shift from pure simulation to general virtualization. New products are increasingly being developed entirely virtually—from concept to development to testing. In this revolution, we simulation experts are pioneers.

What special challenges did you face in the welding project?

We faced several challenges, such as simulating the keyhole regime (see image)—a typical phenomenon in high-power-density processes. This means high temperatures and material evaporation.

Schematic representation of welding regimes with low and high-intensity laser beams | © BSH Hausgeräte GmbH

Parameterization was also an important and complex step. In collaboration with CADFEM, we wrote specific Matlab and APDL scripts for this. Optimization was also a major challenge. We used machine learning-based methods such as the multi-fidelity approach and Bayesian optimization. It was all quite complex, but useful and ultimately led to success.

By reducing the processing time from more than 15.5 days to just 3.5 days, we achieved a time saving of more than 75 percent. This not only makes us much faster but also allows us to calculate and compare many more variants, enabling us to present our customers with the best solutions.

How would you define the "lessons learned"?

We are not only very satisfied with the results of this specific project but also with the competencies we acquired over the three years. First, we can easily transfer the aspects we developed in this project to other projects. Second, we not only found a method to tackle such problems but also defined a framework that leads us to the desired solutions.

Can you describe in more detail what kind of tasks the framework is suitable for?

The main application area is optimization. In this regard, many of the insights we gained and methods we developed can be directly transferred to other projects. Whenever we are challenged by many parameters and complex relationships, we can rely on this framework to optimize faster and more reliably.

What are the next goals regarding the project work?

A major goal for us now is to create an integrated solution of simulation and AI—from the development of digital twins to the implementation of metamodels for predicting temperatures and stresses, to intelligent automation.

In these areas, I can imagine some focal points where we will again need corresponding task force teams. These would be ideal opportunities to continue the very positive collaboration with CADFEM and also with the University of Trieste.

With AI integration, we are able to exploit the simulation potential even more intensively. This allows us to broaden the scope of simulation, making it usable for more users and going deeper into individual applications. As a result, questions that arise can be answered more quickly and comprehensively.

Moreover, our medium-term goal is "Virtual Release." This will allow us to release new or modified products more easily without numerous physical experiments. We plan to release the first products completely virtually starting in 2030.

You can watch the full interview here:

FAQ

-

What are the benefits of using a metamodel?

- Simulation data is used to train the metamodel.

- The metamodel is based on the Kriging method (Gaussian Process). The solution is a weighted linear combination of known points.

- With the metamodel, it is possible to make predictions (mean value) across the entire range and obtain an error quantification (variance).

-

What is meant by Bayesian Optimization?

- The metamodel allows for quickly finding the optimum.

- If only a few training data are available, the solution may be inaccurate.

- Instead of using a large number of DOEs, the concept of Bayesian optimization is to iteratively add new samples only in the interesting area.

-

How does the multifidelity approach work?

- Input data can have different quality (fidelity) levels.

- The idea of the multi-fidelity approach is to combine data with different fidelity levels to train the model.

- For example, it is possible to find the optimum with a few high-quality data points and a larger amount of more cost-effective data.

- Training data is weighted in hierarchical order.