Using simulation to create durable switches

Alexander Kunz

03.06.2025

How JUNG improves standard products using digital development methods

Architects, builders, and building technicians value the design, quality and functionality of JUNG switches. Their durability is further enhanced by innovative digital simulation methods.

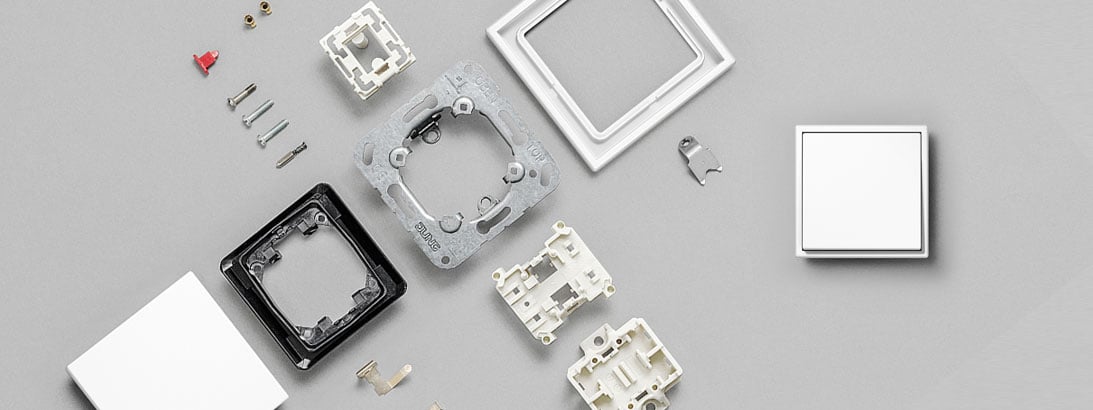

Switches are standardized series products. The project described was carried out on the 506U type switch model. | © JUNG

Switch systems from JUNG stand for innovation and aesthetic design in building control | © JUNG

These switches for controlling light sources, energy systems and various smart home functions are inconspicuous but nevertheless make their mark on rooms and buildings. While the visible front side aims for aesthetics and harmony with the room design, the inner workings with the switching mechanism ensure that the desired electrical processes are precisely triggered over the entire product life.

JUNG from Schalksmühle, a small town in the Sauerland region of Germany, is a leading manufacturers of switch systems for various purposes. True to the company motto “Progress as tradition”, the product range is continuously being developed.

The switches, “Made in Germany”, are always the first choice for architects, craftsmen and developers. After all, the name JUNG symbolizes high-quality switches, which are becoming increasingly sustainable. In addition to the ecological and economical use of materials and energy-efficient production, sustainability is also reflected in a long product life.

What contributes to a long product life?

How can the life cycle of switches be improved? This is more complex than it first appears. After all, we are talking about standardized series products that are described by a large number of national and international standards and that have to function reliably under very different and hardly reproducible conditions. Each individual switch is exposed to various stresses, depending on the place of use, environment, installation, function or the intensity and frequency with which it is operated. The rule of thumb is that fast and permanent closure of the electrical contact with minimal bouncing effects increases the life cycle. This also prevents damaging processes such as arcing.

Switches are standardized series products. The project described was carried out on the 506U type switch model. | © JUNG

Satisfied customers, higher returns, better for the environment

What does a switch need to look like so that it functions reliably in all scenarios due to a short bounce time? A switch that benefits everyone:- The customer from its longevity.

- The environment from its sustainability.

- The manufacturer because the market rewards effective innovations, and because even the smallest savings quickly add up to relevant cost benefits for mass-produced products.

Innovation dynamics instead of innovation pressure

Innovation is considered a key driver of the economy. It creates competitive advantages, fosters growth, boosts efficiency, and enhances customer satisfaction – in short: it drives success.

What to expect in this White Paper (in German)

- Why Innovation Needs Simulation

- Learn how to integrate simulation into your product development process

- We debunk common simulation myths

- And answer frequently asked questions

Digital methods as the key

The digital transformation at JUNG has progressed significantly, especially in the area of product development. Testing and simulation now go hand in hand, with simulation being carried out using Ansys Mechanical. One thing was clear: simulations were the key to optimizing the switch design. However, the resources available to realize the full potential of a holistic simulation approach were not sufficient. This is because the goal of “determining the best design for all scenarios” not only requires consideration of the smallest details in the switch mechanism, but also of the large variance of factors influencing the bounce behavior during product use. Special tools and expertise are required.

Developers at JUNG turned to CADFEM, their partner for simulation and supplier of their own Ansys license. In addition to selling ANSYS, Inc. software and all associated services, CADFEM, which has its headquarters in Grafing near Munich and other locations, including Hanover, also offers simulation services.

This led to the formation of a joint project team consisting of switch specialists from JUNG and simulation experts from CADFEM. After analyzing the task, boundary conditions, and objectives, the combined use of two Ansys software tools emerged as the best solution:

The model of the switch with the contact mechanism is the starting point for simulation-based optimization. | © JUNG

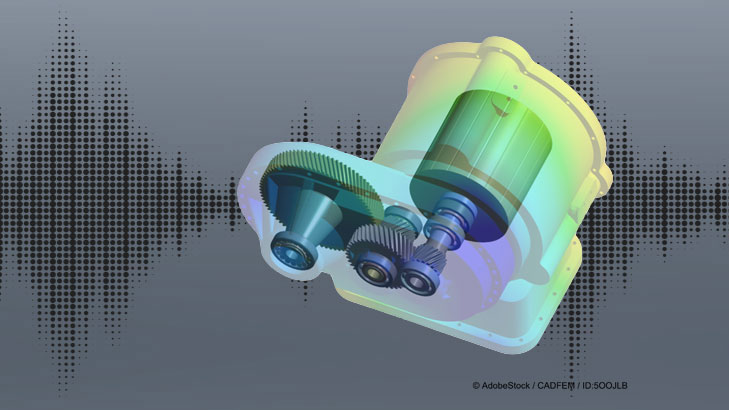

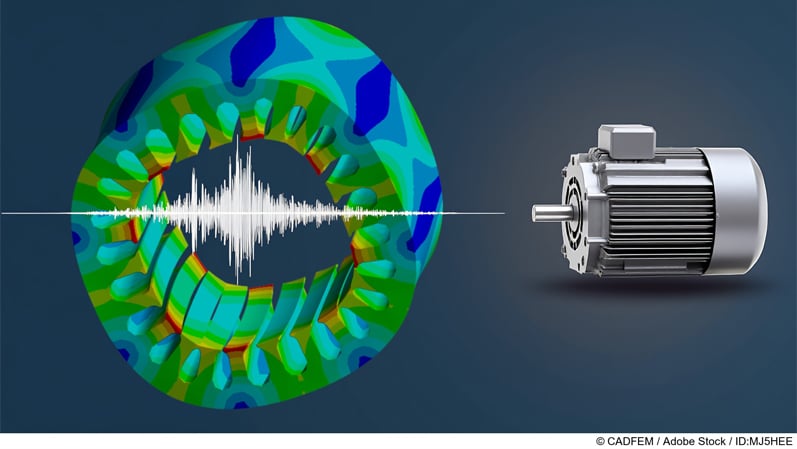

- Ansys LS-Dyna for explicit structural-mechanical simulations. This involves short-term dynamic processes such as those that occur during the switching process. Engineers refer to this as “bounce behavior”. During simulation, the movement is divided into small time steps. The process and, in particular, the resulting contact are modeled and can thus be understood in detail. While electrical measurement methods essentially analyze the behavior at “contact on” or “contact off”, simulation allows additional insights, namely a look inside. In this way, design modifications can be derived that have a positive effect on the wear of the switch under specified conditions.

- Ansys optiSLang for variant and sensitivity studies. All parameters previously identified as having an influence on wear are varied and evaluated. The parallel consideration of the parameters, which also includes the results obtained with LS-Dyna, creates an overall picture from which the most favorable combination is determined. This also includes the various constellations to which the switch is exposed. This procedure leads to the design that delivers the best performance, or the lowest common denominator, so to speak, of all the scenarios addressed.

The bounce behavior in the contact area is analyzed using Ansys LS-Dyna. | © JUNG

Simulation allows us to look at our product from a different perspective. It helps us gain new and additional insights, which in turn are very valuable for measurements on the test bench. Simulation and testing complement each other perfectly - especially when the results are almost identical.

The joint project was carried out in four steps:

In the first step, the CAD model of the type 506U switch was prepared for the simulation. The relevant areas such as the contact apparatus were precisely modeled, while the areas with no influence on the result were simplified. This massively reduced computation times. Based on this, Ansys LS-DYNA was used to analyze the switching movement and bounce behavior.

In the second and third steps, the data was parameterized in order to be able to carry out sensitivity studies. Initially in a reduced form so that the influences could be estimated and weighted. Then, taking into account all data in a very detailed form, allowing correlations and interactions to become visible.

In the fourth and final step, the design was optimized based on the findings. It was verified by another bounce simulation with Ansys LS-Dyna and a real prototype test.

A response surface shows the results of the sensitivity analysis from Ansys optiSLang, allowing engineers to visualize and optimize the influence of various parameters on the preload duration. | © JUNG

Explicit Structural Mechanics Using Workbench LS-DYNA

In this training, you will learn how to simulate quasi-static processes (forming/joining) and dynamic processes (drop test/crash) with LS-DYNA.

More than just a test: Simulation creates lasting competitive advantages

JUNG is very satisfied with the results. The modified switch is more durable, and the analyses also showed that it is even possible to save material during the redesign. By reducing the material thickness of the contact rocker, it was possible to significantly reduce the weight and use of resources. The strong agreement between simulation and testing also confirmed the reliability of the approach developed together with CADFEM. It gives JUNG twice the security, even with complex tasks, and more opportunities to implement innovative ideas - especially in the context of sustainability. As a family-run company, JUNG aspires to achieve this in a global competition with its “Made in Germany” solutions.

The approach also shows how simulation and testing ideally complement each other in terms of an optimal development result and how simulations – also in cooperation with a suitable partner – can be successively expanded in a results-oriented manner.

About JUNG

Innovation, passion and precision have been guiding our product developments for 110 years. Light, shading, air conditioning, energy, security, door communication and multimedia – JUNG systems provide the appropriate solution for every requirement. Aesthetic design combined with intelligent smart home and smart building technology. All systems follow a simple concept: smart and beautiful. The solutions are modern, but not trendy. They are aesthetic and functional, intuitive in use and technically innovative.

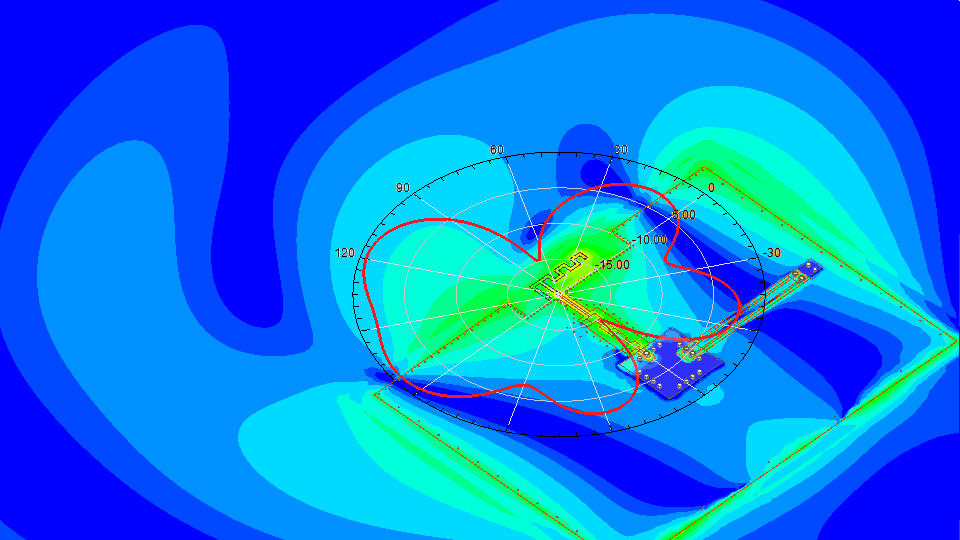

Ansys HFSS

Industry standard for determining the radiation and transmission behavior of high-frequency electromagnetic fields.