Four Myths About Thermal Radiation Simulation

Ulf Friederichs

14.11.2025

TechArticle 25/10 | From Mythical Tales to the Radiant Reality of Simulation

What impact does hours of sunlight have on a steering wheel? I’ve “painfully analyzed” it myself in the Swiss summer: 70 °C on the surface. Thanks to thermal simulations in Ansys Mechanical, I can now understand the interplay of conduction, convection and radiation - without the blisters. A look at four common myths reveals when radiation becomes a decisive factor.

Temperature distribution on a steering wheel exposed to sunlight | © CADFEM (Suisse) AG / Adobe Stock

Can Ansys Mechanical simulate thermal radiation?

The answer is clear: With Ansys Mechanical, you can simulate all three heat transfer mechanisms you probably remember from university. Conduction transfers energy through molecular contact or electron transport, typically in solids. Convection describes heat transport via the movement of fluids or gases, where warm regions rise and cold ones sink. Here, we roughly distinguish between free and forced convection. Radiation, finally, occurs via electromagnetic waves - like solar radiation - and requires no medium.

|

Conduction |

(Lattice vibrations and electron transport) within and between (contacting) solids |

Fourier’s Law |

|

|

|

|

|

|

|

|

Illustration of the three heat transfer mechanisms that can be simulated in Ansys Mechanical | © Adobe Stock

In the finite element analysis (FEA), heat conduction is classically modeled using the material property of thermal conductivity. Based on the geometry, a thermal network of many calculation nodes is created, which can be solved numerically. From this, heat fluxes and temperatures are determined. Convection is typically defined as a boundary condition and describes the heat flux density at an external surface toward the surrounding fluid. Here, the heat transfer coefficient plays a key role. Both thermal conductivity and convection coefficient can be realistically defined as temperature-dependent.

Fun-fact: Thermal radiation with moving bodies

Temperature profile over 12 hours with a moving radiation source (sun) | © CADFEM (Suisse) AG

Thermal radiation is special in two ways: first, due to its dependency on the fourth power of the temperature in Kelvin, and second, in FEA, because it allows heat transfer across undefined space. As you’ll see later, Ansys Mechanical offers several ways to simulate thermal radiation. Things get particularly interesting when the radiation source - like in the video - is moving. That’s actually a question we often get in support. I’ll show you later how to simulate that.

Is thermal radiation only relevant above 200 °C?

Good question! Let’s take a closer look at the specific application case of thermal radiation affecting our steering wheel example: It’s obvious that without radiation, the steering wheel would only reach the ambient temperature - here, 35 °C. But it locally heats up to 69 °C, precisely where sunlight hits most directly. You might say that solar radiation only matters here because the sun’s surface is thousands of degrees hot. That’s true - even though the sun is over 100 million kilometers away. So, is the final answer “no”?

How strongly does thermal radiation affect the temperature field? To answer this, let’s virtually move into the shade and simulate the cooling of the steering wheel under these new conditions. We observe the following:

- Without considering radiation (only convection and conduction), the temperature drops more slowly.

- With radiation included, it drops significantly faster.

- In short: even in the relevant temperature range of around 50 - 70 °C, thermal radiation plays a major role!

Are the kinks in the temperature curves physically accurate? Good question: The kinks in the global maximum temperature curve occur because the thin upper section of the steering wheel cools down quickly, and the location of the temperature maximum then shifts into the thermally more inert metal body.

Maximum surface temperature of the steering wheel in the shade over time (blue: with radiation, orange: without thermal radiation) | © CADFEM (Suisse) AG

Temperature field of the steering wheel after 144 seconds, left: without, right: with thermal radiation influence (pink area: > 50 °C) | © CADFEM (Suisse) AG

This behavior can be explained as follows: On the one hand, the absolute surface temperature measured in Kelvin plays a role; on the other hand, the difference to the radiation exchange partner also has an impact. Due to the fourth-power dependency, a similar heat flux occurs between 200 °C and 189 °C as between 69 °C and 35 °C. This means: even at lower temperature levels, radiation can generate a significant heat flux - provided the temperature difference is large enough. So the myth can clearly be answered with a “yes and no”!

Is thermal radiation difficult to calculate?

Let’s start with the simplest level: thermal radiation to the environment. In this case, Ansys Mechanical solves the Stefan–Boltzmann equation for each node on the selected part surfaces, using the absolute ambient temperature T2 you’ve predefined.

![]()

That’s almost as straightforward as accounting for convection, which follows Newton’s law. All you need to do is select the relevant surfaces and enter the ambient temperature and emissivity. Computation time and memory usage remain virtually unchanged.

It gets more interesting when we want to simulate radiation between surfaces - for example, between the surface of the sun and the surfaces of the steering wheel. This is mainly a geometric challenge, since not every part of the steering wheel is exposed to sunlight at the same angle. The shaded areas don’t “see” the sun at all. We’re talking about view factors here, which mathematically describe this correlation for all surface elements within a radiation domain.

So, is it complicated after all? Not for you: the truly demanding task of calculating view factors is handled by the Radiosity Solver in Ansys Mechanical.

View factor distribution on a sphere, relative to one element on a rectangle | © CADFEM Suisse AG

What is the role of the Radiosity Solver in Ansys Mechanical?

- Calculation of the view factor matrix:

- Computes view factors between all surface elements within a radiation enclosure

- Generates the file vf based on these calculations

- Computation of radiative heat fluxes:

- Based on the current temperatures of the radiation elements

- According to the Stefan-Boltzmann law

- The radiation heat transfer solver uses the calculated heat fluxes as boundary conditions.

You must manually specify the correlation and, if applicable, a number for the radiation enclosure in the boundary condition settings. If you represent moving components (e.g. moving heat sources) in a Coupled Field Transient simulation via displacements, you should set Update View Factors to Every Substep.

Settings for Surface-to-Surface Radiation (S2S) in Ansys Mechanical | © CADFEM (Suisse) AG

Thermal Radiation simulation is resource-intensive

You have now seen that Ansys Mechanical puts considerable effort into surface-to-surface radiation. And yes, this effort can result in increased memory usage (e.g. the file.vf) as well as longer computation times. However, there are ways to minimize both effects.

|

Measure |

Effect |

Reduces Memory Usage |

Reduces Computation Time |

|

Defining multiple separate radiation zones1 |

Reduces overall size of the view factor matrix |

|

|

|

Select only relevant radiation surfaces |

Reduces overall size of the view factor matrix |

|

|

|

Parallelization across multiple CPUs (HPC) |

Speeds up both view factor calculation and thermal simulation |

|

|

|

Reusing view factor matrices (APDL commands VFOPT and /COPY) |

Avoids repeated calculation of view factor matrices |

|

|

|

Avoid meshing radiation surfaces finer than necessary or apply surface clustering/decimation (APDL command RDEC)2 |

Reduces overall size of the view factor matrix |

|

|

|

Compressing view factor matrices (APDL command VFOPT) 3 |

Eliminates zero entries |

|

|

Tools to reduce memory usage and computation time | © CADFEM (Suisse) AG und Adobe Stock

With these tools, you can significantly reduce memory requirements and computation time - making thermal simulations with radiation economically feasible even for larger models.

1: For example, if you can identify two radiation zones of approximately equal size, you can halve the memory usage and reduce computation time even further.

2: In the steering wheel example, a 50% decimation reduced the computation time on my laptop from 217 seconds by a factor of 5 to just 42 seconds.

3: Compressing the view factor matrices reduced the size of the view factor file by a factor of 10 in the steering wheel example.

Temperature field calculation on your side

Do you now see that thermal radiation can indeed be considered in Ansys Mechanical? Did you get ideas for future cool steering wheels while reading? Dive deeper into the topic in the eLearning or the seminar Temperature Field in Ansys Mechanical. There you'll learn how to realistically model emissivities, view factors, and time- or location-dependent loads - and perhaps we’ll even get the chance to exchange ideas directly:

- Do you use plastic components that tend to lose up to 40% of their strength and stiffness between 20 °C and 60 °C?

Temperature effect on the stress-strain curve of a high-performance polymer | © CADFEM (Suisse) AG

- Which components in your application suffer from elevated temperatures?

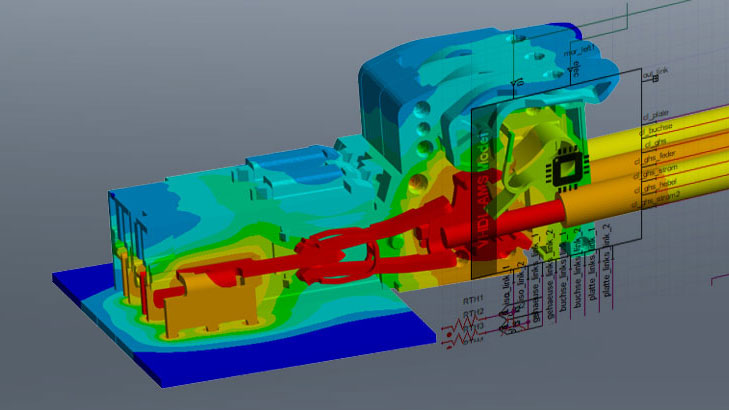

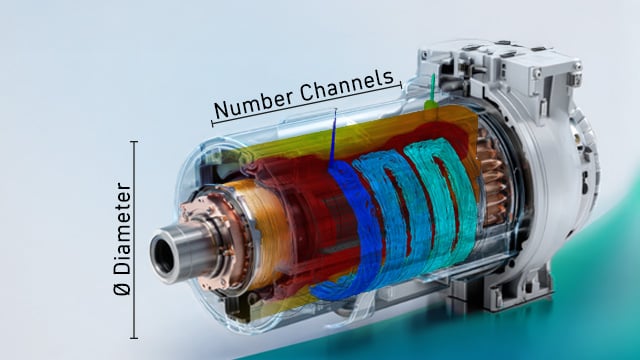

Sensors, LEDs, electric machines, and many other electronic components are exposed to high thermal loads due to high power densities or ambient temperatures. - Where do elevated temperatures reduce lifetime, performance, or efficiency?

High temperatures negatively affect material properties - for example, the electromagnetic efficiency of electric motors, component wear due to thermal expansion, or changes in lubricant characteristics in bearings. - Do you want to get thermal distortion, thermal stresses, or residual stresses under control?

Then get in touch with us! Learn or deepen your understanding of thermal simulations in Ansys Mechanical. Our Temperature Field seminar gives you confidence in conduction, convection, radiation, and thermo-mechanical coupling

Training Tip

Finite-Element-Based Heat Transfer Simulations

Learn how to perform thermal analyses in Ansys Mechanical: best practice for heating and cooling tasks and determination of thermal stresses.

Ansys Fluent GPU Performance Testing – Use Case

Ob im Maschinenbau, in der Luftfahrt oder bei der Produktentwicklung: Strömungssimulationen sind für präzise und schnelle Entwicklungsprozesse unerlässlich. Doch wie unterscheiden sich CPU- und GPU-basierte Simulationen, und was sind die wichtigsten Kriterien bei der Hardwarebewertung? Dieser Beitrag beleuchtet grundlegende Unterschiede, Leistungsmetriken und die Anwendungsmöglichkeiten von GPU- und CPU-Setups für Ihre CFD-Projekte.t

More on the topic

-

Let's Simulate: Temperature Field with Feed

Learn how to simulate the stationary temperature field of a welding process with practical tips on heat and mass transport modeling in solids and fluids.

-

Multiphysics Simulation with Ansys Mechanical

In this training, you will learn about the theory and practical application of coupled field simulation for the interaction of mechanics, temperature and electricity.

-

TechArticle: Welches ist die richtige Schweißgeschwindigkeit?

Welding processes generate a lot of heat output in the smallest possible area, which is why adapted process control is important in order to avoid defects and reduce welding beads - especially those on the forehead. Find out here why 5 mm/s is the right speed for this application and how it could be even faster.