Ansys, Engineering, AI: A talk with Erke Wang und Matthias Hoermann

Alexander Kunz

13.09.2024

„We have always had an international mindset“

In the global Ansys community, not many names are more well-known than that of Erke Wang. In the following interview, Erke Wang, along with Matthias Hörmann (both technical directors of CADFEM Germany) discuss the close ties between Ansys and CADFEM, a few key highlights, the importance of AI and the value of ecosystems.

Erke, when and how did you join CADFEM?

EW: Back in 1988, the VDI and the Ministry of Mechanical Engineering in China wanted to promote the exchange of young engineers. I was selected and my first stop was CADFEM. In fact, Günter Müller picked me up at Munich-Riem airport. Beijing to Grafing was a huge culture shock. Nevertheless, on my first day in the office, I encountered familiar things: computers from DEC, a Tektronix terminal and Ansys 4.2. I have fond memories of my first colleague, Peter Tiefenthaler, whose warm Bavarian demeanor was a tremendous help to me. I am so grateful that Ansys has connected me with so many fantastic people around the world.

How long have you been familiar with Ansys?

EW: In 1984, I was a simulation engineer at the computer center in Beijing and Ansys chose us as a local partner. However, hardly anyone in China spoke English back then. So I translated all of the Ansys manuals into Chinese. Maybe that's why I still know most of the APDL commands, i.e. the Ansys scripting language. By the way, my record time for creating an Ansys APDL macro (geometry creation, meshing, solving and post-processing) for a plate with a hole under tensile load is 29 seconds. It should be noted, however, that back then a model with 1,000 elements was considered a large model. Beam elements, spring elements, mass elements, 2D elements and 3D shell elements were all used.

© CADFEM

Erke Wang (EW)

was born in Shanghai and first came into contact with Ansys in 1984, which has stayed with him ever since. In 1988, Erke went to Germany on a scholarship and quickly became one of the faces of CADFEM. He has been the technical managing director of CADFEM Germany since 2009.

Matthias, what did you think of Erke when you started at CADFEM?

MH: I spent the first eight months at the CADFEM office in Chemnitz, where I became familiar with LS-Dyna and deepened my knowledge of composites, which was the subject of my doctorate. When I moved to the Grafing office, I began having daily contact with Erke, who still impresses me with his knowledge and enthusiasm for Ansys and technology in general. He is driven by the success of our customers and has really left his mark on CADFEM. Moreover, Erke's wise words on all life situations are astounding.

AI utilizes the huge wealth of data generated in engineering and thus raises the efficiency of simulation to a new level.

Ansys has now been around for over 50 years. What do you consider to be important milestones on this journey?

EW: The term “milestone” does not do justice to the dynamism that Ansys displays. Where should I start? Ansys has always set standards with automated meshing, CAD integration, multiphysics, system simulation, HPC, the Workbench interface - the list is endless. Millions of engineers benefit from this and are able to develop products faster, more precisely and with fewer resources. With its pioneering solutions and innovations, Ansys has contributed to the digital transformation in engineering being more advanced than in other areas. Since simulation-based virtual prototypes represent physics so well, they are superior to real tests in all respects, especially during the development process. This saves time, money and promotes innovation, as it is possible to quickly evaluate whether a new idea works.

CADFEM develops end-to-end simulation process and data management (SPDM) with its customers on Ansys Minerva. | © CADFEM

MH: Another remarkable thing is how many physical domains are covered. This makes it easier for companies to use simulation in a strategic way, as does the ability to automate, customize, democratize and integrate it into company processes. There is no way around this in the course of digital transformation. Certified partners such as CADFEM provide support during implementation. Ansys established a partner network early on, which was both forward-looking and customer-oriented - a “milestone”, so to speak.

What do you think the future holds?

MH: The topic of sustainability is of paramount importance. Digital simulation-based engineering has already achieved a lot in terms of resource conservation and a functioning recycling economy - but it can and must achieve even more. In concrete terms, digital engineering contributes to sustainability, alone from the number of prototypes that do not have to be built. A much greater effect is triggered when the ecological footprint of a product, especially a mass-produced product, can be influenced in the earliest design phase, for example by selecting materials based on many contributing factors.

EW: One opportunity is AI. We can see that AI and ML (machine learning) are bringing simulation closer to an ideal world, with a perfect balance of time, effort and results. AI utilizes the huge wealth of data generated in engineering and thus raises the efficiency of simulation to a new level. ML will enable companies to increase test accuracy through intelligent measurements and reduce real-world tests to the absolute minimum necessary.

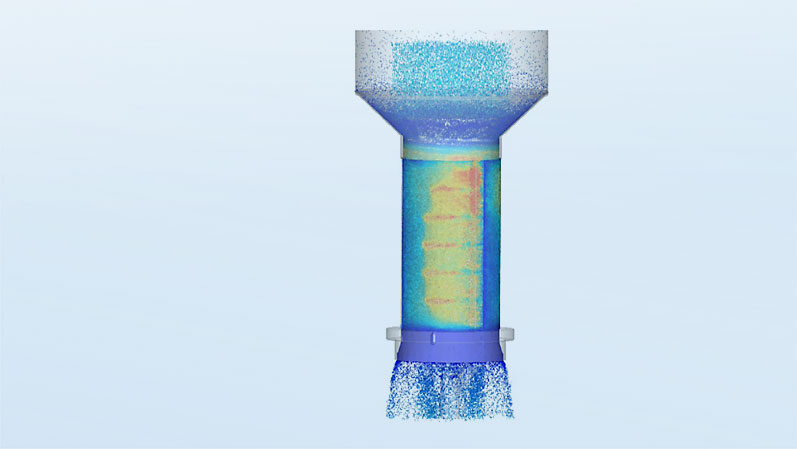

Among other things, CADFEM develops customized simulation solutions for customers. | © CADFEM

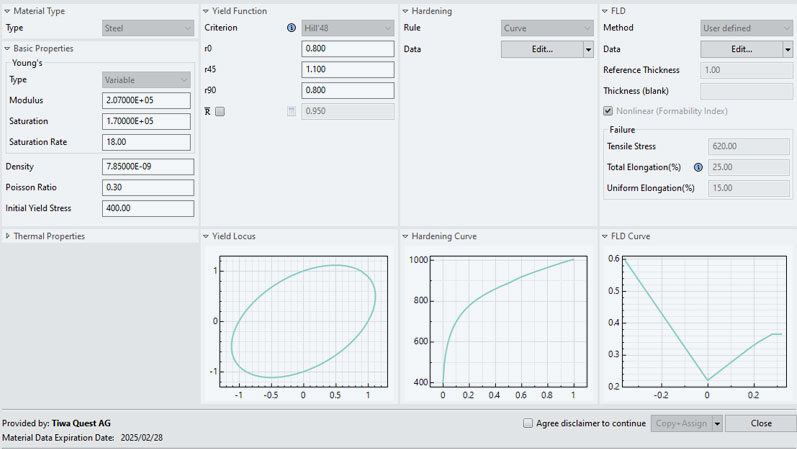

MH: In order to deliver added value, all these data must be clear, transparent and consistent. This brings us to SPDM (simulation and process data management), whose relevance is massively increased by AI. SPDM is the basis for the automation and therefore scaling of simulation. Application apps will make simulation a reality for every engineer. Thanks to standardization in the programming language for engineers, Python has become a fundamental knowledge for engineers, and software providers such as Ansys have converted their software APIs to Python, enabling customers to easily use the software for automation.

CADFEM is the driver of many Ansys initiatives such as Workbench, Digital Twin, AI and ML, as well as the integration of applications and products like optiSLang, Motion and Motor-CAD.

How are customers and the industry currently reacting to major shifts such as AI?

EW: We have felt the impact of AI at our conferences. Over 1,000 people attended our Blueprint panel discussion on AI in June - twice the usual amount! The fact that demand for automation and SPDM are growing at the same time shows that our customers see both topics collectively.

MH: Yes, the interest in AI is stunning, not just at events, but in the community in general. However, we are also seeing concerns about whether our own expertise and skills will still be in demand in the future. I say yes! In fact, perhaps more than ever. However, transparency, understanding and acceptance of new initiatives are the keys to success. A joint assessment of potential and benefits is absolutely essential. This not only allows the real benefits to be identified and pilot projects to be initiated, but also sends a clear message to stakeholders and employees in the company that everyone is on board.

© CADFEM

Dr.-Ing. Matthias Hörmann (MH)

decided to join CADFEM in 2003 after completing his doctorate at the University of Stuttgart. Matthias has worked in various areas of the company and knows from many perspectives of CADFEM, simulation and digital engineering. He was appointed to the management board in 2023.

Back to Ansys and CADFEM. What connects the two?

MH: As we have already mentioned, Ansys has a strong partner network that is close to its customers. As the largest Ansys partner worldwide, CADFEM has been part of the company from the very beginning. But there's much more that connects us.

EW: That's right. CADFEM has expertise in the entire Ansys portfolio. Our support regularly receives top ratings, and our training program, which consists of over 110 courses and eLearnings, is number one for practice-oriented CAE. Our customers know that they can rely on CADFEM when it comes to Ansys as well as topics in SPDM, AI, new fields of application and special tasks. Ansys also knows this, which is why they recommend us as a channel, service and technology partner.

MH: We also work together with Ansys. CADFEM is the driver of many Ansys initiatives such as Workbench, Digital Twin, AI and ML, as well as the integration of applications and products like optiSLang, Motion and Motor-CAD, just to name a few. This makes us proud. We will continue to help shape simulation in the interests of our customers in the future.

EW: The integration of American software technology, German precision and Bavarian generosity has created a long-lasting and mutually trusting partnership.

The integration of American software technology, German precision and Bavarian generosity has created a long-lasting and mutually trusting partnership.

… and everything is international, right?

EW: We have always had an international mindset. The CADFEM Group puts this conviction into practice and CADFEM's expertise, services and technology are used worldwide.

MH: Thanks to our internationality with local presences, customers are served in their language, time zone and culture. Every Group member also benefits from the synergies in terms of knowledge, specialization and capacity management. What also distinguishes the CADFEM Group ecosystem is that, in addition to the connection with Ansys, it includes partners with special simulation expertise in medicine, mobility, urban planning, energy, Big Data and AI, for example.

There it is again, AI. Thank you very much for the interview.

The interview was conducted by

Alexander Kunz

CADFEM Germany GmbH

+49 (0)8092 7005-889

akunz@cadfem.de