Process automation with Ansys in the early development phase

Martin Meiler

26.09.2025

TechArticle 25/08 | Variant study using the example of a heat pump

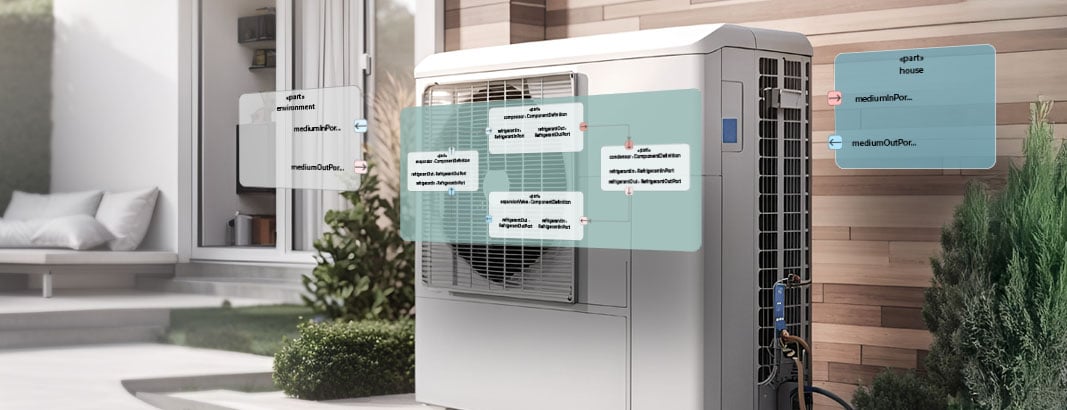

As product complexity increases, methods for process integration and design optimization are becoming increasingly important. Using the example of a heat pump, it is demonstrated how Process Integration and Design Optimization (PIDO) makes expertise from various disciplines accessible and supports system engineers in identifying optimal solutions already in the early stages of development.

PIDO-based design process using the example of a heat pump | © Adobe Stock/CADFEM Germany GmbH

Process Integration in Systems Engineering

A new product does not simply come into existence — it is the result of collaboration between a wide range of stakeholders, disciplines, and experts. Whereas coordination was previously often document-centric, there is now a growing shift toward model-based methods. The advantage is clear: there are dedicated data repositories for requirements, architectures, product lifecycle management (PLM), xCAD data, and much more. This results in unambiguous information, and no department or employee can work with outdated data, as everything is accessible via a web-based browser interface, including full data history.

In systems engineering, numerous activities need to be coordinated — among them, the alignment of requirements, development of functional and technical architectures, and coordination of component variant identification, all in collaboration with the relevant departments. Traditionally, the specialist departments were asked to design one or more variants of a component. This involved discussing possible variations, designing associated variants, and checking whether the requirements were met. This time-consuming process was carried out for various components across different departments and carried a high risk of errors due to uncoordinated changes or miscommunication. What this process cannot easily achieve, however, is optimization at the product level. This is precisely where process integration comes into play.

Illustration of the information flow during product development | © CADFEM Germany GmbH

Democratization of expert knowledge

The involvement of various specialist departments in the design process poses an organizational challenge for the Systems Engineering team. Dependencies must be recognized and taken into account during the development process. If a redesign is necessary after the completion of the entire process, the complete process must be undergone again. Until now, the communication process, in which requirements for the component to be developed or provided are exchanged, has mostly taken place through documents, emails, or meetings. The result of the specialist department's design was communicated back to Systems Engineering in a similar way and format.

In the case of high workload within the specialist department, there was a risk of project delays, as prioritization of active projects had to take place. In addition to the time required for executing the various design and calculation tools, there is also the risk of information errors that can occur during data transfer in both directions. Therefore, a process is desirable where information can be utilized directly rather than being transferred. If this process can be automatically initiated via defined data interfaces, information errors and time issues can be eliminated.

Above: Example of the manual process. Below: Example of a democratized component | © CADFEM Germany GmbH

This democratization of expert knowledge requires validation steps for the model component as well as the definition of validity ranges for the input parameters. In practice, it is beneficial to use descriptive names for the components as well as naming conventions for defining inputs and outputs, and to provide information regarding boundary conditions and application notes. Additionally, the explicit specification of units for inputs and outputs also plays an important role, which is crucial in international teams and in the mixed use of imperial and metric units. If possible, SI units should be used to avoid conversion errors.

Faster development through process automation

For the product development process and systems engineering, democratization allows access to expert knowledge at any time. This enables quicker assessments in systems engineering regarding the feasible components of a product. As a result, the development process can be significantly accelerated. Benefits also arise for the departments and the experts working there. Repetitive tasks are now eliminated with validated and published workflows. Therefore, the experts have time to focus on the development of new solutions or the democratization of further behavior models. The valuable development time of subject matter experts can now be concentrated on value-adding tasks through democratization.

Thus, the creation of behavioral model components for both systems engineering and the specialist departments represents a win-win situation. However, in new developments, this advantage can only be utilized to a limited extent. When completely new concepts are introduced, where there is a lack of experience and trust in the models, democratization must be postponed until a certain Technology Readiness Level (TRL) of the new components is reached, until the necessary validation and verification steps have been completed.

System optimization through interdisciplinary models

The faster design process is not the only advantage. As a by-product, the product can now also be optimized at the system level. In the classical process, serial coordination between development departments made it difficult and time-consuming to take into account the impact of design changes on other components. The interaction of component behavior models and automated data exchange allow both local optimization of individual components and the determination of an optimal product configuration.

The representation of the complete product design process offers another advantage. At the product level, the relevant design parameters can now be identified for each objective. Through statistical experimental design (or Design of Experiments), variant studies and careful sampling of the parameter space, the sensitivity of the objectives to the influencing parameters can be determined. This step is mandatory for subsequent optimization tasks, as it reduces the number of relevant, independent design parameters and narrows the variation bandwidth.

In today's globalized and connected world, development activities not only take place at one single location, but are distributed across multiple sites, possibly in different countries, continents, and time zones. How can democratization or data exchange take place in this context? This is where Ansys ModelCenter comes into play. With the Remote Execution functionality, it is possible to establish a Remote Execution Server for each department, on which process components can be published and executed. Required programs and licenses are thus provided at the location of the technical department and managed by the subject matter experts.

Exemplary representation of the networked design process using remote execution servers of the individual departments and locations | © CADFEM Germany GmbH

PIDO- based design process of a heat pump

Finally, using a heat pump, it is demonstrated how an automated design process can look. A heat pump typically uses a CFC-free refrigerant. In the external evaporator, the liquid refrigerant is heated and evaporated by the outside air. Using an electrically driven compressor, the pressure and temperature of the gaseous refrigerant are increased. The heat transfer of the higher temperature refrigerant to the room temperature occurs in the condenser, where the refrigerant condenses back into the liquid state. Ultimately, the refrigerant flows back through a pressure reducing valve to the evaporator, where the cycle starts again.

Simplified architecture of a heat pump with heat flow interfaces to the outside world and into the house. | © CADFEM Germany GmbH

In this example, we are not evaluating the “in-house” development of components such as compressors or pressure regulating valves. Instead, the role of the system integrator is taken on, and an optimal product is identified from available component catalogs. Components and a refrigerant are selected based on various catalogs, and relevant metrics such as total costs, Coefficient of Performance (CoP), and noise emission are examined.

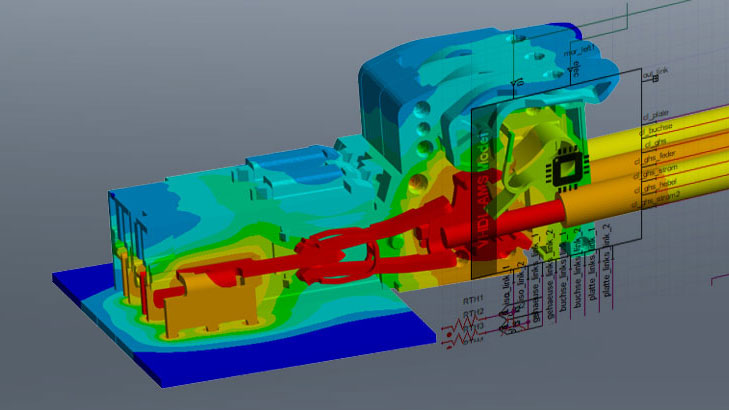

Automated workflow in Ansys ModelCenter for calculating noise emissions, CoP, and total costs. | © CADFEM Germany GmbH

The automated workflow presented here was created in Ansys ModelCenter. This representation shows the relevant influencing parameters as well as the output variables of the workflow. Data connections are visible through the connections between the components. If you want to develop such models yourself, it’s worth taking a look at the second season of Let’s Simulate – Safe and Secure Systems. There, you will see a live demonstration of how structured, modular workflows are formed. Or you can expand your expertise in a targeted manner with the CADFEM eLearning course on Ansys ModelCenter. Here, you will learn how to confidently set up complex models and take system development to the next level. In addition, you will receive valuable information on the automated determination of optimal parameters through the CADFEM seminar on Ansys optiSLang.

Finally, it should be noted that the behavioral models realized in Ansys ModelCenter can also be linked to corresponding architecture models. For this purpose, the new Ansys System Architecture Modeler is suitable, which is the centerpiece of Ansys’ Digital Engineering strategy. This will be introduced in a future TechArticle.

FAQs

What is PIDO?

PIDO is the abbreviation for Process Integration and Design Optimization. Process integration describes the interplay of different behavioral models, including the data exchange between the components. Design optimization refers to determining a mathematical optimum by specifying one or more objective functions, where boundary conditions and restrictions of the possible range of values can also be defined. Automated optimization is possible with Ansys optiSLang.

What does democratization refer to?

In the context of behavioral models, democratization refers to the provision of expert knowledge through validated components. In this case, output quantities are calculated based on possibly domain-restricted input parameters.

Tip

Let’s Simulate – Safe and Secure Systems

Functional safety in the product development process - which strategies help you achieve your goal

Tipp

eLearning: Ansys ModelCenter: Prozess-Integration & Design-Optimierung

Frühe Designideen automatisieren und systematisch bewerten: Mit Ansys ModelCenter identifizieren Sie vielversprechende Entwürfe bereits in der Konzeptphase. Diese Schulung wird als eLearning-Kurs mit freier Zeiteinteilung angeboten.

Ansys Fluent GPU Performance Testing – Use Case

Ob im Maschinenbau, in der Luftfahrt oder bei der Produktentwicklung: Strömungssimulationen sind für präzise und schnelle Entwicklungsprozesse unerlässlich. Doch wie unterscheiden sich CPU- und GPU-basierte Simulationen, und was sind die wichtigsten Kriterien bei der Hardwarebewertung? Dieser Beitrag beleuchtet grundlegende Unterschiede, Leistungsmetriken und die Anwendungsmöglichkeiten von GPU- und CPU-Setups für Ihre CFD-Projekte.t

Seminare zum Thema

-

Let’s Simulate – Safe and Secure Systems

Funktionale Sicherheit im Produktentwicklungsprozess - mit welchen Strategien Sie ihr Ziel erreichen.

-

eLearning: Ansys ModelCenter: Prozess-Integration & Design-Optimierung

Frühe Designideen automatisieren und systematisch bewerten: Mit Ansys ModelCenter identifizieren Sie vielversprechende Entwürfe bereits in der Konzeptphase. Diese Schulung wird als eLearning-Kurs mit freier Zeiteinteilung angeboten.

Training on the topic

-

Ansys ModelCenter: Process Integration & Design Optimization

Automate and systematically evaluate early design ideas: With Ansys ModelCenter, you can identify promising designs as early as the concept phase.

-

Improve and Analyze Products with Ansys optiSLang

Learn how to examine parameter influences, robustly optimize properties, process signals and integrate processes in Ansys.

Author

Martin Meiler

Business Development Manager Safe Systems

+49 (0)8092 7005-121

mmeiler@cadfem.de